Plast Hen is one of Israel’s leading fiberglass factories, specializing in the production and execution of fiberglass works tailored to a wide range of industrial needs. Our plant uses only the highest-quality raw materials, ensuring engineering precision, compliance with strict quality standards, and creative solutions for every project. Our fiberglass products are widely applied in water and wastewater infrastructure, the chemical industry, construction, and even in unique design and art projects-delivering the winning combination of strength, durability, and design flexibility. With extensive experience and advanced technological capabilities, we provide a full service package: from design and production to rehabilitation, coating, and sealing of existing structures, all under one roof in a professional fiberglass plant.

What is FRP - Fiberglass?

Fiberglass (FRP - Fiber Reinforced Plastic) has become one of the most important materials in both the Israeli and global industries. It is a composite material made from glass fibers reinforced with polymer resins, offering an exceptional balance of high mechanical strength, low weight, and outstanding resistance to corrosion and chemicals. These properties make fiberglass the material of choice for manufacturing a wide variety of products-from large industrial tanks and pools to access components such as ladders and platforms.

At Plast Hen, we operate an advanced fiberglass factory supported by a skilled professional team that also performs fiberglass work on-site. This allows us to provide a complete solution-new production, coating, and rehabilitation of existing facilities- all tailored to each project’s requirements.

FRP Manufacturing and Customized Solutions

Our production facilities manufacture a diverse range of customized FRP products, including:

- Fiberglass tanks - for storage of acids, bases, and corrosive solutions, with optional internal liners matched to the chemical type.

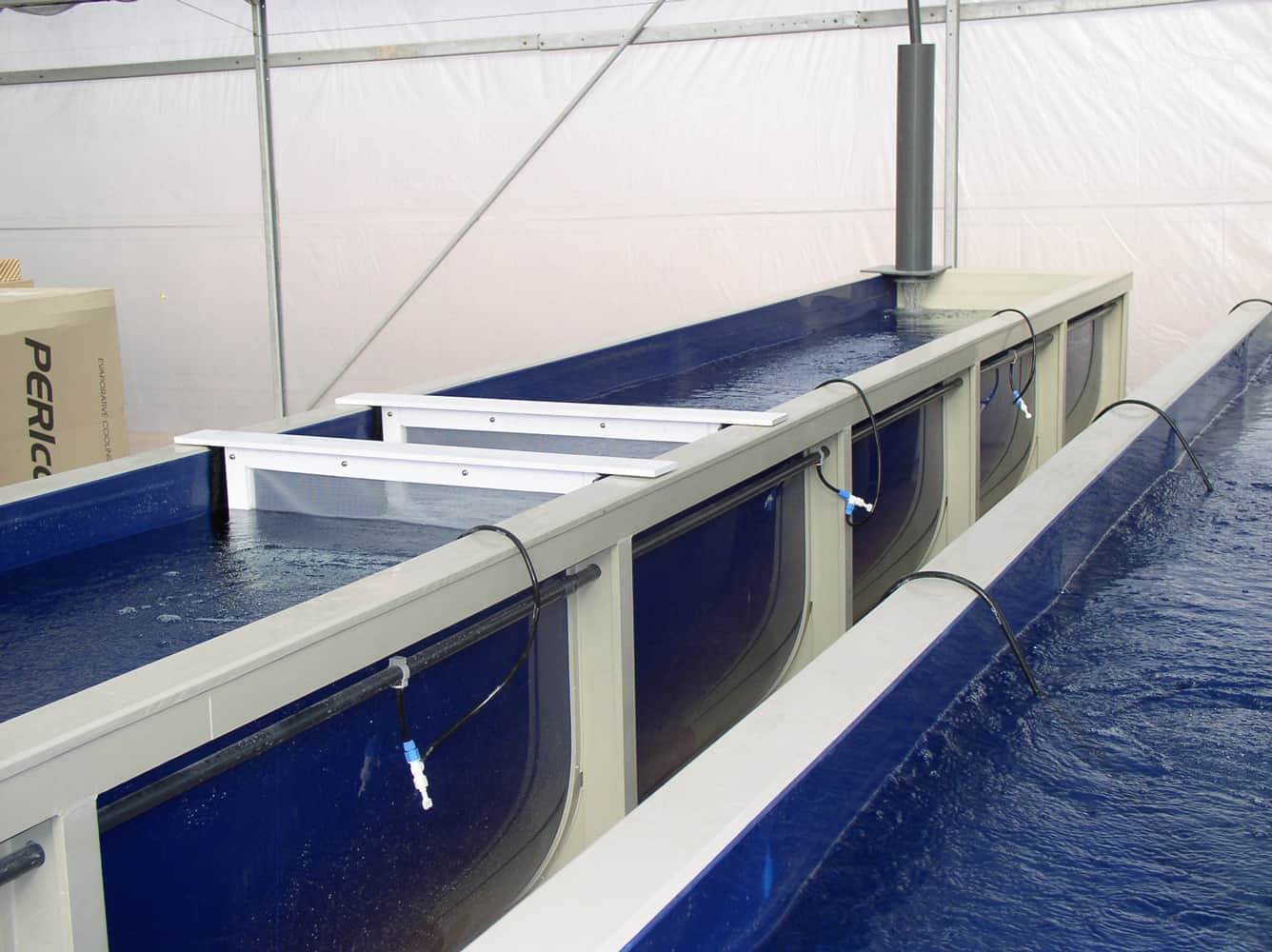

- Fiberglass pools - for industry, agriculture, or decorative use, reinforced with FRP for added structural strength.

- Containment basins - for collecting chemical spills and leaks, designed to meet stringent environmental regulations.

- Platforms and access structures - anti-slip solutions that ensure safe access and operation around industrial facilities.

- FRP ladders and gratings - lightweight, chemical-resistant, easy to install and maintain.

Every project is engineered according to loads, temperatures, chemical exposure, and site conditions, with full compliance to international standards such as ISO and DVS.

On-Site Fiberglass Works

One of our key areas of expertise is on-site fiberglass applications. Often, a new facility is not required-the correct solution is coating or rehabilitating an existing structure.

- Concrete containment basin lining - applying an internal FRP layer that is fully sealed, preventing chemical penetration into concrete pores and ensuring long-term regulatory compliance.

- Concrete tank lining - a quick, cost-effective solution for improved sealing and corrosion protection.

- Reinforcement of existing structures - adding FRP layers to repair cracks, strengthen openings and supports, or extend the service life of aging systems.

- External coatings - for enhanced structural strength and protection in harsh outdoor environments.

The coating process is carried out in defined stages: surface cleaning and preparation, structural repair, placement of glass fiber laminates with specialized resins, application of UV-protected gel coat, and final sealing tests.

Advantages of Fiberglass Compared to Other Materials

- Excellent chemical resistance - suitable for most acids, bases, and salts.

- Lightweight - simplifies transport and installation, reducing load on the infrastructure.

- High structural strength - enables the production of large installations without metallic elements.

- Corrosion resistance - a major advantage over steel and concrete.

- Design flexibility - ability to adapt diameters, shapes, openings, and accessories to any requirement.

- Minimal maintenance - smooth, easy-to-clean surfaces with anti-slip options for access components.

Industrial Applications

Our fiberglass solutions are implemented across diverse industries:

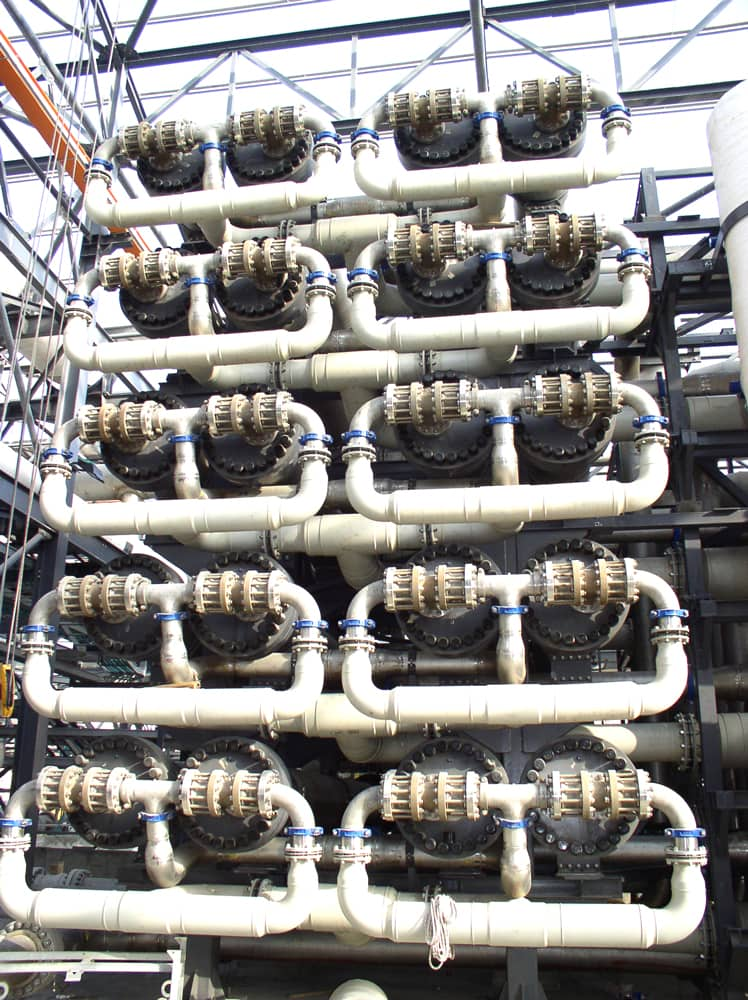

- Chemical and petrochemical - tanks, scrubber columns, containment basins.

- Water, wastewater, and desalination - ducts, chimneys, and concrete linings.

- Food and pharmaceuticals - sterile, easy-to-clean surfaces.

- Agriculture - fiberglass pools and durable irrigation solutions.

- Energy and infrastructure - FRP access components, structural reinforcements, exposed piping.

Conclusion

Fiberglass works combine engineering knowledge, advanced composite materials, and design flexibility. At Plast Hen, we provide both new manufacturing of fiberglass tanks and fiberglass pools, as well as the coating and rehabilitation of existing concrete containment basins and tanks-solutions that ensure safety, durability, and long-term cost savings. The combination of an advanced fiberglass factory with tailored on-site works makes us a trusted professional partner for any industrial project requiring reliability and true expertise.