Over the past several decades, a clear trend has emerged across the industrial sector: a steady shift toward piping and duct systems made from thermoplastic materials. Whether in private construction projects or large-scale industrial and commercial installations, engineers, architects, and manufacturers increasingly prefer plastic-based solutions due to their clear advantages over traditional materials such as steel or cast iron.

What Are Thermoplastics?

Thermoplastics are a broad family of polymers that can be heated, shaped, and cooled repeatedly without losing their essential properties. This characteristic allows for efficient manufacturing, high adaptability to various project requirements, and long-term durability.

The most common thermoplastic materials used in piping and duct systems include:

- PVC (Polyvinyl Chloride) - Widely used in sewage, drainage, and cold-water systems.

- PP (Polypropylene) - Commonly used for hot-water piping thanks to its excellent heat resistance.

- PE (Polyethylene) - Suitable for gas lines, cold-water distribution, and industrial infrastructure.

Key Advantages of Thermoplastic Piping and Ducts

🗸 Exceptional durability - Unlike metal pipes, thermoplastic materials do not rust and are highly resistant to corrosion.

🗸 Lightweight construction - Their low weight simplifies handling, transportation, and installation, while significantly reducing logistical costs.

🗸 Fast and simple installation - Thanks to their flexibility and modular connection systems, thermoplastic pipelines can be installed quickly and efficiently.

🗸 Design flexibility - Thermoplastics can be tailored to the specific needs of each project, offering a high level of customization.

🗸 Reduced maintenance costs - The long-lasting nature of these materials minimizes the need for frequent repairs or replacements.

Common Applications

- Hot and cold-water systems - PP and PE pipes are ideal for safely transporting water at a wide range of temperatures.

- Sewage and drainage systems - PVC has become a global standard thanks to its strength and proven performance.

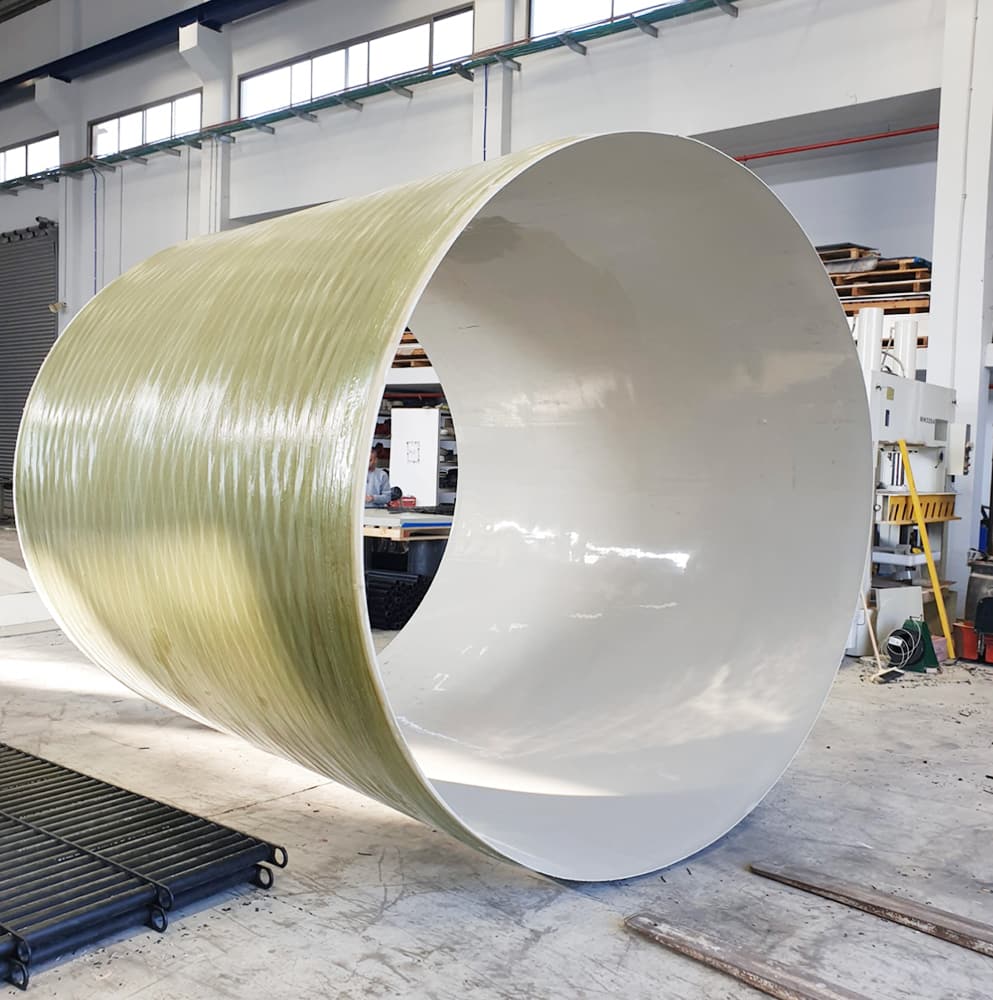

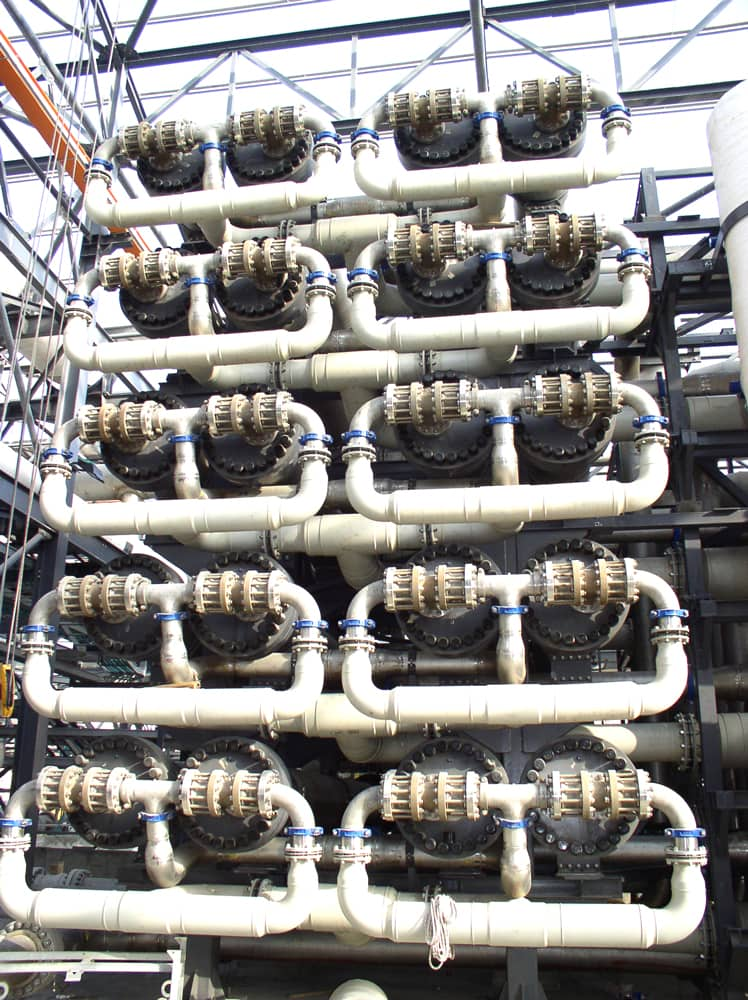

- Industrial systems - Thermoplastic ducts are used to transport chemicals and aggressive fluids in harsh industrial environments.

- Agricultural projects - From irrigation networks to water channels and greenhouse infrastructure, plastic piping plays a vital role in modern agriculture.

Comparison to Traditional Steel Piping

Steel and iron pipes are heavy, prone to rust, and require ongoing maintenance. In contrast, thermoplastic piping maintains reliable performance for many years, is significantly easier to install, and allows greater flexibility in design and on-site modifications.

Conclusion

Thermoplastic materials have become the standard in modern piping and duct systems - and for good reason. They deliver superior durability, efficiency, flexibility, and long-term cost savings. For engineers, planners, and industrial operators, choosing thermoplastic piping is a smart investment in reliable and innovative infrastructure.