Slotted and Perforated Pipes - A Custom Solution for Drainage, Filtration, and Ventilation

In the world of infrastructure, engineering, and agriculture, challenges related to drainage, filtration, and ventilation are common. Standing water in the soil, liquid accumulation in tunnels, or insufficient ventilation in industrial processes can cause significant operational and economic damage. This is where slotted and perforated pipes provide an effective, reliable, and versatile solution, manufactured precisely according to project specifications.

At Plast Hen, we specialize in producing slotted pipes with diameters of up to 350 mm, fully customized for each project. The slotting process is carried out using advanced computerized equipment, ensuring high precision in every slot - with density, positioning, and angle defined during the design stage.

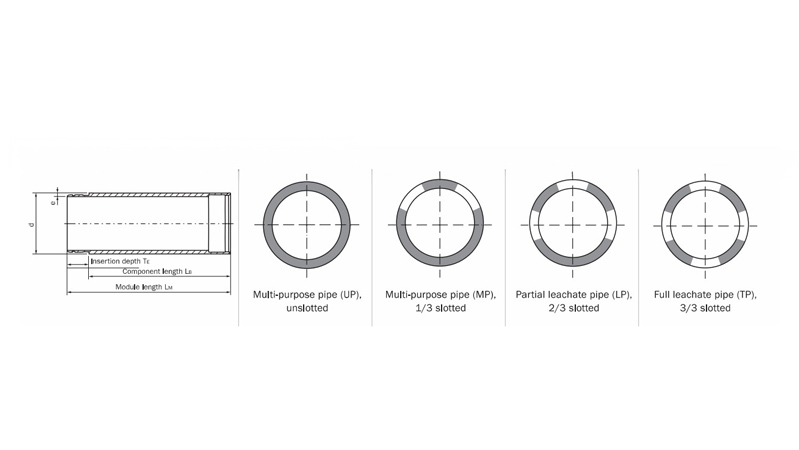

What Is Pipe Slotting and Why Is It Important?

Pipe slotting or perforation is a process in which carefully measured slots are cut along the pipe wall. These slots allow controlled passage of water or air in and out of the pipe.

In practice, the pipe functions not only as a transport conduit but also as an active engineering element that supports drainage, filtration, and ventilation.

Key design parameters include:

- Slot density - determines the flow rate of water or air through the pipe.

- Slot positioning - circumferential, longitudinal, or point-specific, depending on the application.

- Slot angle - enables control of the flow direction.

Each project receives a tailor-made specification, ensuring that the pipe delivers the exact performance required.

Material Selection - Matching Pipes to Project Requirements

At Plast Hen, we manufacture slotted and perforated pipes from a wide range of thermoplastic materials, selected according to field conditions:

- HDPE (High-Density Polyethylene) - exceptional resistance to UV radiation, chemicals, and abrasion. Ideal for agricultural and outdoor applications.

- PP (Polypropylene) - suitable for industrial processes involving higher temperatures or chemical exposure.

- PVC (Polyvinyl Chloride) - a common choice for urban drainage systems and the food industry, thanks to ease of processing and strong chemical resistance.

Proper material selection ensures long service life and reduced maintenance costs.

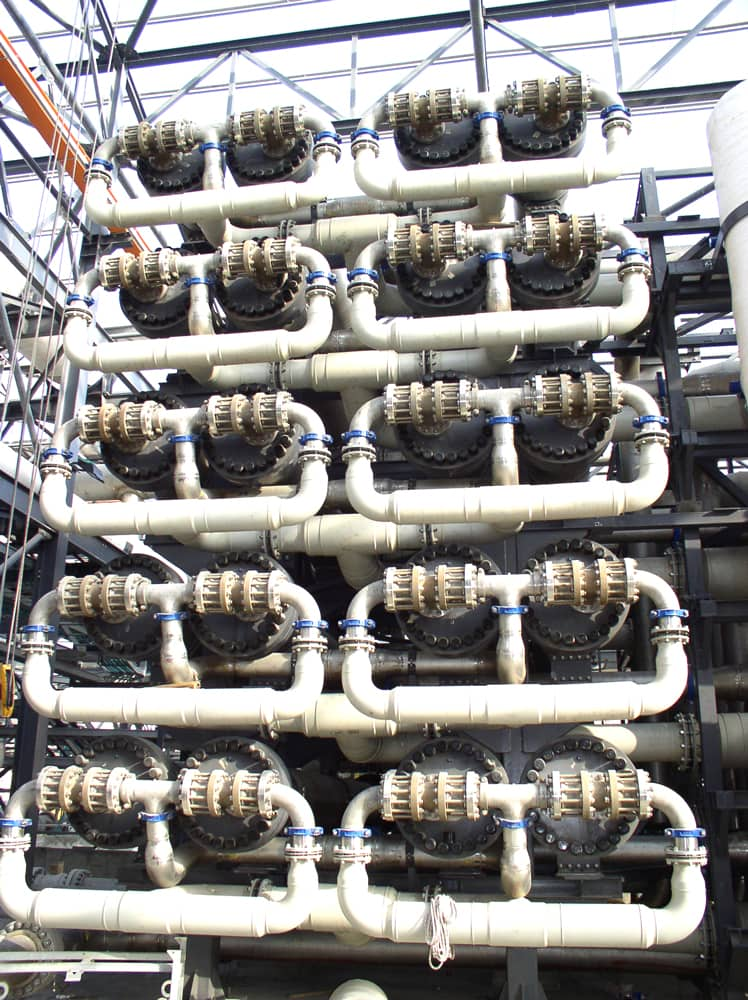

Common Applications of Slotted and Perforated Pipes

Slotted and perforated pipes are widely used in applications where controlled water or air flow is required:

- Subsurface drainage and groundwater filtration - prevents water accumulation, stabilizes soil, and protects engineering structures.

- Tunnel ventilation and drainage - a critical safety solution in large infrastructure projects.

- Agriculture - smart irrigation systems, field drainage, and soil quality improvement in orchards and greenhouses.

- Water and wastewater treatment - integrated into advanced filtration and aeration systems.

- Urban and industrial projects - upgrading existing systems or building new networks with tailor-made piping.

Slotted Pipes Compared to Alternative Solutions

In many projects, alternatives such as gravel layers or drainage sheets are considered. However, slotted and perforated pipes offer clear advantages:

- Precise flow control - density and positioning of slots can be designed to match project needs.

- Higher durability - thermoplastic pipes are resistant to wear, corrosion, and harsh site conditions.

- Reduced maintenance - a simple, clean, and long-lasting solution that requires minimal upkeep.

Key Advantages of Slotted and Perforated Pipes

- Custom manufacturing - produced according to required diameter, wall thickness, and slot design.

- Design flexibility - slots can be arranged in various patterns to create unique solutions.

- Long-term durability - excellent resistance to chemicals, UV exposure, and abrasion.

- System efficiency - reduces stress on pumps, drainage systems, and filtration units.

- Cost savings - lower operational and maintenance costs compared to alternatives, with extended service life.

Quality Control and Standards

At Plast Hen, slotted and perforated pipe production is carried out under strict quality control and in full compliance with international standards.

Each slot is inspected according to the project’s specifications to ensure uniformity, mechanical strength, and long-term resistance to site conditions.

The result: a high-quality, reliable product you can count on for years.

Plast Hen - Experts in Slotted and Perforated Pipe Manufacturing

We offer complete, tailor-made pipe production solutions, including:

- Pipe diameters up to 350 mm.

- A wide range of premium raw materials.

- Precise engineering design according to usage requirements.

- Professional support from our experienced engineering team - from design through on-site installation.

Conclusion

Slotted and perforated pipes are an advanced engineering solution that provides efficient, reliable performance for drainage, filtration, and ventilation needs.

The combination of precise slotting, high-quality materials, and custom engineering design ensures a durable, cost-effective, and dependable system.

With Plast Hen’s extensive expertise, you can be confident that every project will receive the exact solution it requires - from initial planning through installation - while meeting the strictest international standards.

👉 Learn more about our slotted pipe manufacturing services and discover how Plast Hen can deliver the perfect solution for your project.