The Need for Durable Ventilation Systems

In modern industry, ventilation systems are not merely a matter of comfort - they are critical for safeguarding worker health, ensuring compliance with environmental regulations, and maintaining uninterrupted production. In industrial facilities that release gases, vapors, or aggressive chemicals, the demand for corrosion-resistant ventilation systems becomes even more pressing. This is where polypropylene (PP) ventilation and air-conditioning ducts come into play - a thermoplastic material that combines exceptional chemical resistance with lightweight construction and engineering flexibility.

What is Polypropylene and Why is it Suitable for Corrosive Environments?

Polypropylene (PP) is a partially crystalline thermoplastic polymer characterized by:

- High chemical resistance - especially against strong acids, bases, chlorides, and ammonia.

- Thermal stability - continuous operation up to ~90°C, withstanding temperature fluctuations without losing structural integrity.

- Lightweight design - PP ducts are much lighter than stainless steel or aluminum, simplifying installation and transportation.

- Smooth internal surface - prevents buildup of contaminants, dust, or chemicals, making it ideal for high airflows.

Compared to metallic materials, polypropylene does not rust, degrade in humid or aggressive environments, or require costly coatings and frequent maintenance.

Common Industrial Applications

Polypropylene ducts are widely used across various industrial sectors, including:

- Fertilizer and cleaning product plants - handling ammonia and sulfuric acid vapors.

- Pharmaceuticals and biotechnology - sterile HVAC systems resistant to disinfectants.

- Food industry - ducts exposed to frequent chemical cleaning without structural damage.

- Metal finishing and coating plants - neutralizing acid vapors in electrolysis and galvanization processes.

Advanced Manufacturing Technologies

The production of PP ducts involves:

- Extrusion and hot welding - creating sealed seams as strong as the base material.

- Multi-layer reinforcement - designed for enhanced resistance to pressure and stress.

- Engineering customization - diameters, wall thicknesses, and shapes tailored to airflow dynamics and installation conditions.

These ducts can be seamlessly integrated into existing systems or installed as part of new ventilation designs.

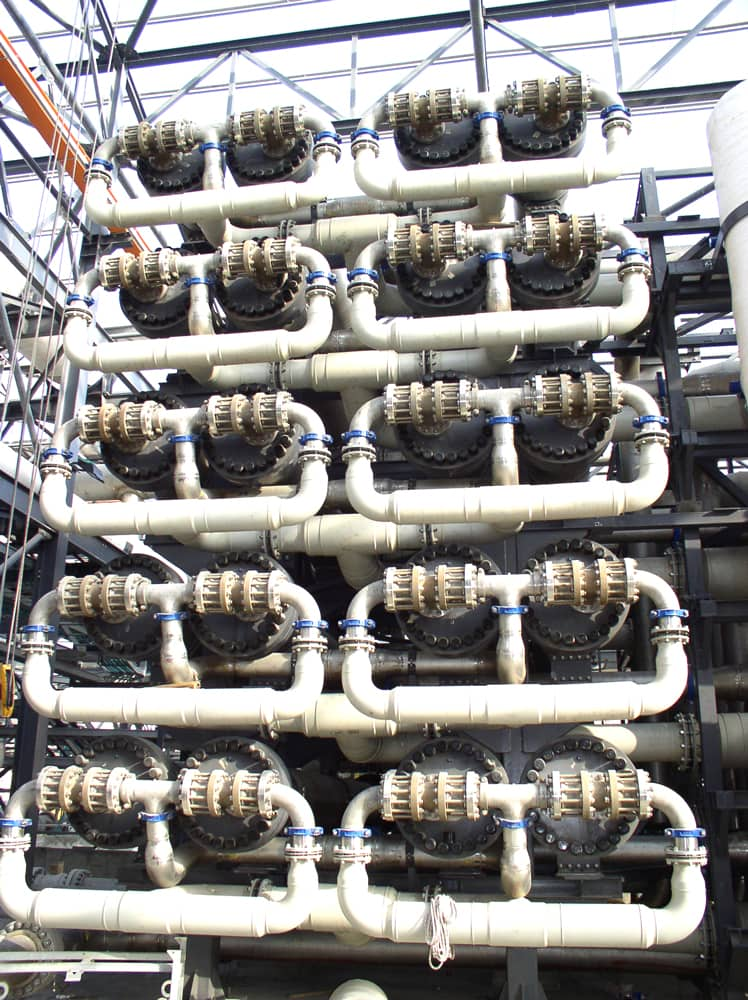

Mist Eliminators and Cyclones - Essential Components

An industrial ventilation system does not end with the ducts. Additional components often include:

- Mist Eliminators - preventing liquid droplets from entering the airflow, protecting sensitive equipment and reducing wear.

- Cyclones - using centrifugal force to remove solid particles, serving as a first line of defense before advanced filtration.

Integrating PP ducts with these components ensures complete durability and efficiency, even in the most challenging environments.

Cost vs. Benefit - Life Cycle Cost (LCC)

At first glance, PP duct installation may appear slightly more expensive than conventional materials. However, a life cycle cost (LCC) analysis reveals clear advantages:

- Reduced downtime for maintenance.

- Lower expenses for repairs and protective coatings.

- Service life of decades, even under corrosive conditions.

- Compliance with environmental regulations - minimizing exposure to penalties.

Ultimately, the long-term savings and reliability far outweigh the initial investment.

Looking Ahead - Innovation in PP Duct Systems

The future points toward hybrid systems that combine PP with composite materials such as FRP, integration of smart monitoring for real-time air quality, and alignment with ESG and Net Zero strategies. More companies are recognizing that investing in durable, eco-friendly solutions is not only a regulatory requirement but also a competitive advantage in the global marketplace.

Conclusion

Polypropylene ventilation and air-conditioning ducts provide a strategic solution for the chemical industry and other advanced sectors. Thanks to their chemical resistance, lightweight structure, regulatory compliance, and long service life, PP ducts have become a global standard wherever clean, safe, and controlled airflow is essential. For industrial facilities seeking long-term savings, legal compliance, and environmental innovation - PP duct systems are the way forward.