In modern industries, filtration processes are essential to ensure product quality, operational safety, and compliance with strict regulatory standards. Among the most reliable solutions available today are polypropylene (PP) filters - thermoplastic-based filters known for their chemical resistance, structural stability, and versatility. PP filters are designed to handle aggressive environments, providing long-term durability while remaining lightweight and cost-effective.

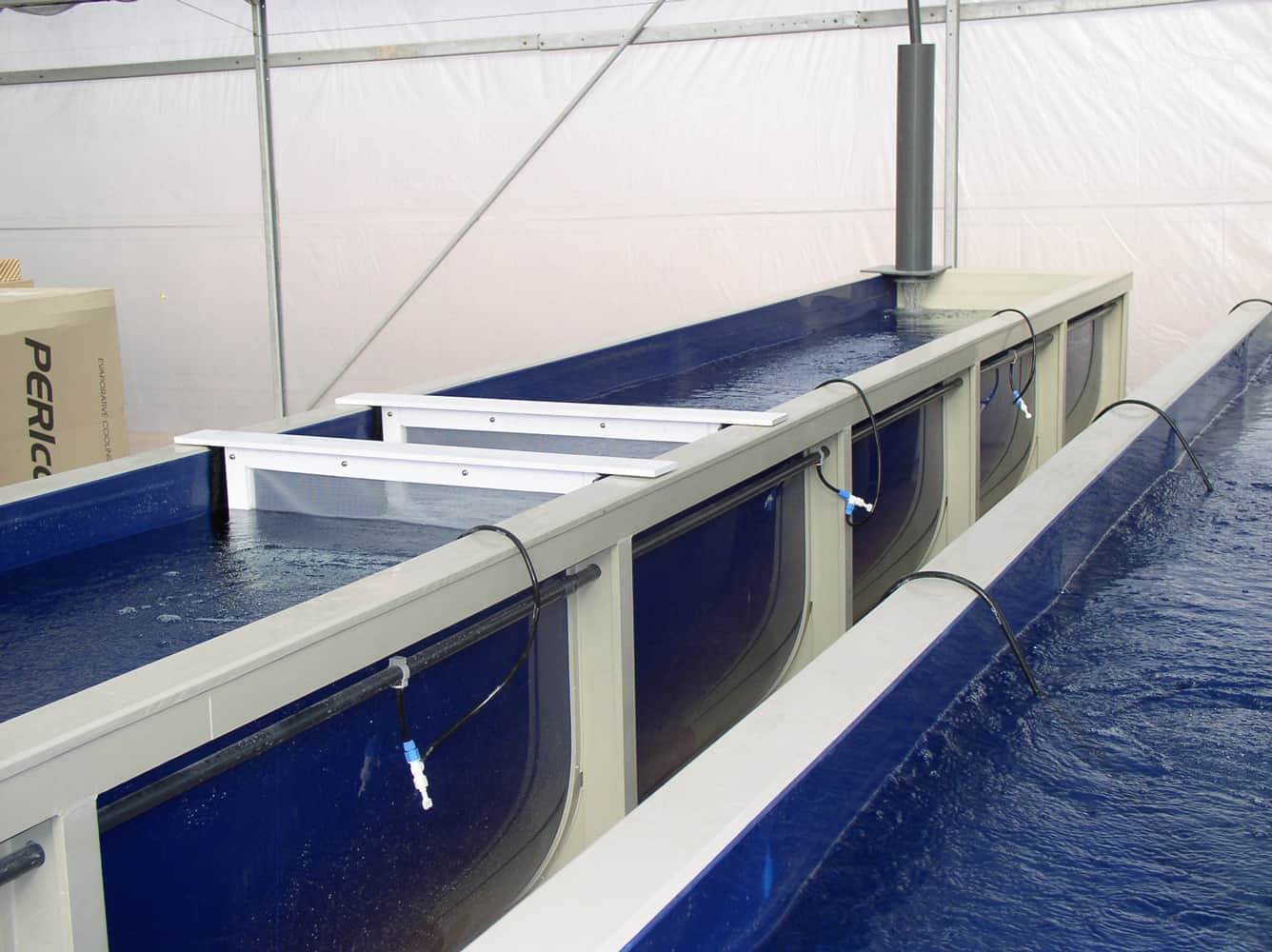

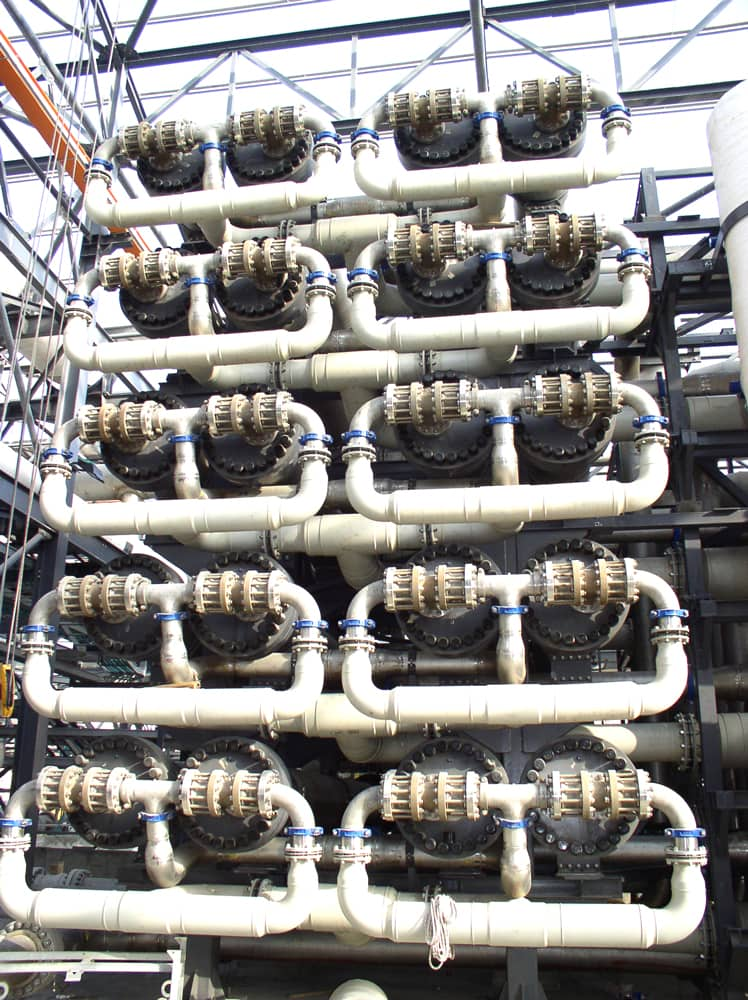

At Plast Hen, we design and manufacture customized PP filters as part of a wider range of thermoplastic filtration solutions that also include HDPE, PVC, PVDF, and GRP. Each filter is engineered according to precise specifications and integrated seamlessly into water treatment systems, chemical processes, food production, and pharmaceutical applications.

What is Polypropylene (PP) and Why is it Ideal for Filtration?

Polypropylene (PP) is a thermoplastic polymer from the polyolefin family, widely used in engineering applications due to its unique combination of properties. It withstands continuous exposure to temperatures up to approximately 90°C, resists acids, bases, and many organic solvents, and offers excellent structural stability. Unlike metals, PP does not corrode, requires minimal maintenance, and is considerably lighter, which reduces installation and transportation costs.

Compared with fiberglass (FRP), PP is more flexible and easier to adapt to custom requirements, making it a preferred choice for projects requiring tailored engineering solutions. Against metallic alternatives, PP holds a clear advantage in terms of long-term cost-effectiveness and reduced maintenance demands.

Key Advantages of PP Filters

Polypropylene filters combine material strength with engineering flexibility, offering several unique benefits:

- Exceptional chemical resistance - suitable for aggressive acids, bases, and corrosive solutions.

- Electrical insulation - a natural property of PP, preventing electrostatic discharge in sensitive environments.

- Lightweight construction - easier installation and reduced load on existing infrastructure.

- Low maintenance - smooth inner surfaces prevent contaminant buildup.

- Modular design - available in cylindrical, basket, inline, or fully customized forms.

- Cost-effectiveness - provides long service life at a lower overall cost compared to metals or advanced composites.

Industrial Applications

Polypropylene filters are now widely implemented across industries that demand efficiency, safety, and reliability:

- Chemical industry - filtration of aggressive liquids during thermal processes, protection of sensitive equipment, and safe handling of corrosive substances.

- Water and wastewater treatment - pre-filtration for desalination plants, industrial wastewater purification, and utility systems.

- Food and beverage production - filtering sugar solutions, oils, and process water while maintaining hygiene standards.

- Pharmaceutical and biotech sectors - sterile fluid filtration and process safety under regulated conditions.

- Advanced agriculture - irrigation systems requiring continuous filtration to prevent clogging.

Custom Design and Engineering Solutions

One of the most significant advantages of PP filters is their adaptability. At Plast Hen, each filter is designed according to engineering specifications tailored to the client’s system:

- Dimensions - diameter, height, and flow capacity are calculated for optimal efficiency.

- Integration features - custom service openings, connections, and support structures.

- Specialized requirements - anti-static options for sensitive applications, or reinforcement for high-pressure conditions.

- Site-specific design - ensuring compatibility with existing systems or challenging environments.

This flexibility ensures that every client receives a filtration solution that is technically precise and fully integrated into their operational infrastructure.

Maintenance and Service Life

Polypropylene filters are designed for longevity with minimal upkeep. The smooth polymer surfaces reduce the accumulation of contaminants, requiring fewer cleaning cycles. When cleaning is necessary, filters can be easily disassembled, flushed, or replaced. Under proper operating conditions, PP filters can last many years - often exceeding a decade - depending on the environment and the type of liquid being filtered.

Conclusion

Polypropylene (PP) filters combine chemical resistance, structural stability, and design flexibility to provide an advanced, cost-effective solution for industrial filtration needs. Whether applied in water treatment, chemical production, food processing, or biotechnology, PP filters deliver long-lasting reliability with minimal maintenance.

With Plast Hen’s engineering expertise, strict quality control, and ability to customize solutions, polypropylene filters can be integrated into any industrial setting, offering efficient performance and dependable operation for years to come.