Plastic Storage Tanks - Durable, Versatile, and Customized Solutions

In today’s industrial and agricultural sectors, plastic storage tanks have become the preferred solution for storing water, chemicals, and a wide range of liquids. Unlike concrete or metal tanks, plastic tanks provide a lightweight, corrosion-resistant, and highly adaptable option that can be tailored to different industries and operating conditions.

Why Choose Plastic Tanks?

The growing demand for plastic tanks comes from their unique balance between strength, flexibility, and cost efficiency. Materials such as polypropylene (PP), high-density polyethylene (HDPE), and fiberglass-reinforced plastic (FRP) allow the production of tanks that withstand aggressive chemicals, harsh outdoor conditions, and mechanical stress.

For water storage applications, large plastic water tanks provide a safe, long-term solution. They maintain high structural integrity, prevent contamination, and comply with international food-grade standards. Drinking water - storage in compliance with FDA food-grade approvals ensures suitability for both residential and industrial use.

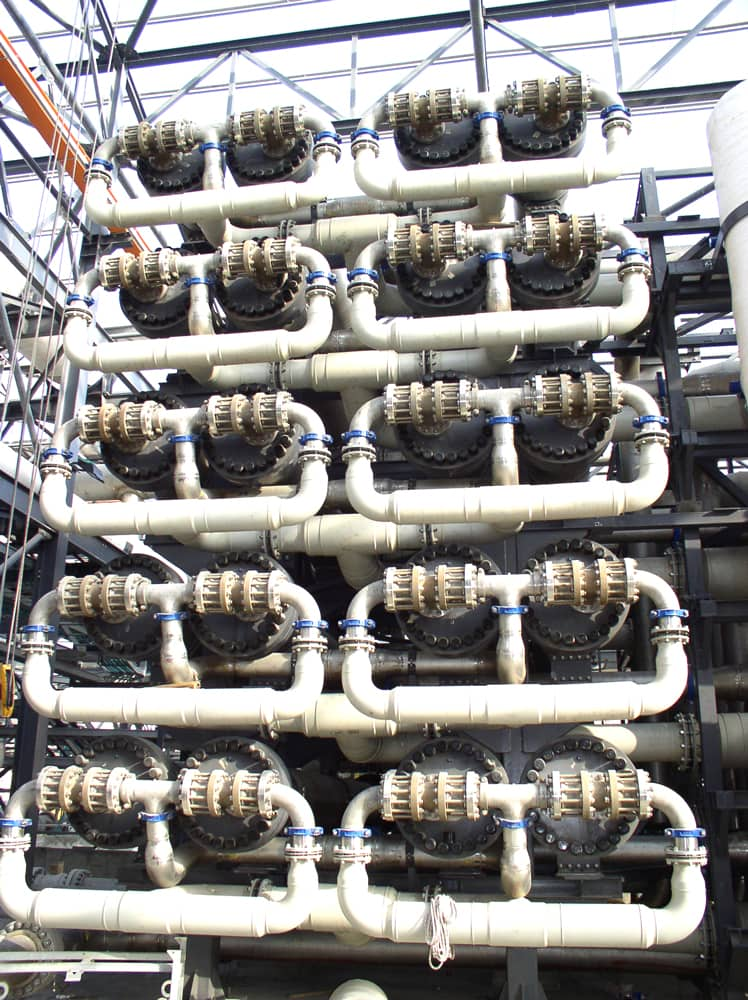

When it comes to industrial facilities, plastic chemical tanks are designed to resist acids, bases, and solvents while maintaining a smooth inner surface that prevents residue buildup. This makes them ideal for chemical plants, pharmaceutical production, and wastewater treatment.

In agriculture, plastic tanks for irrigation are widely used to support high-volume water distribution, fertilizer mixing, and livestock watering. Farmers benefit from tanks that are lightweight, easy to transport, and adaptable to any site, whether in open fields or greenhouses.

Types of Plastic Tanks

At Plast Hen, we manufacture a wide range of plastic storage tanks tailored to specific needs:

- Polypropylene (PP) tanks - resistant to high temperatures and aggressive chemicals, suitable for advanced industrial processes.

- HDPE (polyethylene) tanks - durable, cost-effective, and UV-resistant, commonly used in agriculture, food, and environmental industries.

- FRP (fiberglass) tanks - reinforced with glass fibers for maximum mechanical strength, designed for heavy-duty applications and long-term durability.

Each tank can be produced as vertical or horizontal, with flat or conical bottoms, and with custom openings, fittings, ladders, and platforms.

Applications Across Industries

- Water storage - from small plastic water tanks for households to industrial-size tanks for factories and municipalities.

- Chemical storage - safe handling of corrosive liquids in compliance with strict environmental regulations.

- Agricultural use - irrigation systems, fertilizer mixing, and livestock supply.

- Food and beverage industry - hygienic tanks for production processes and raw material storage.

- Wastewater treatment - customized tanks for collection, neutralization, and recycling processes.

Advantages of Plastic Tanks

The main reasons companies and individuals choose plastic storage tanks include:

- Full resistance to corrosion and rust, unlike steel or concrete.

- Lower weight, which simplifies transportation and installation.

- Long service life with minimal maintenance requirements.

- Custom design flexibility in size, shape, and additional accessories.

- Cost efficiency, both in initial investment and long-term operation.

Cost and Pricing Factors

The cost of a plastic tank depends on multiple factors: capacity, material type, additional reinforcements, and installation complexity. For example, polypropylene tanks are more expensive than polyethylene tanks but offer superior thermal and chemical resistance. Fiberglass tanks provide unmatched structural strength but require a higher investment. Accessories such as valves, level indicators, ladders, and safety rails also influence the total price.

Each project is priced individually, ensuring that the customer receives the most efficient and cost-effective solution for their specific needs.

Conclusion

Plastic storage tanks combine durability, versatility, and affordability, making them an essential component in water management, chemical processing, agriculture, and industrial infrastructure. With advanced manufacturing technologies, Plast Hen delivers tailor-made solutions - from 1000-liter plastic tanks with taps to large-scale industrial tanks - all designed to meet international quality standards and provide long-term reliability.

For expert consultation and customized tank design, contact Plast Hen today.