Introduction

Containment basins, also known as spill containment systems or sump basins, are essential safety structures in industrial facilities that store or handle hazardous liquids. Their primary purpose is to prevent leaks, spills, or accidental discharges from reaching the soil or water sources. By capturing and isolating dangerous substances, containment basins protect the environment, ensure worker safety, and support compliance with regulatory requirements.

Today, containment basins are no longer optional accessories but integral components of modern industrial infrastructure. They are found in chemical plants, pharmaceutical facilities, fuel depots, food processing plants, and water treatment sites.

Materials and Design Options

Containment basins can be constructed from a variety of materials, each with distinct advantages:

- Thermoplastics (PP, HDPE): Lightweight, highly resistant to acids, bases, and salts, and available in custom-fabricated sizes.

- GRP (Glass Reinforced Plastic / Fiberglass): Provides excellent structural strength combined with chemical resistance; suitable for larger installations.

- Concrete or Steel: Traditionally used for heavy-duty structures, but vulnerable to corrosion, cracking, and chemical attack if not lined or coated.

In recent years, thermoplastic and fiberglass basins have become increasingly popular due to their durability, corrosion resistance, and low maintenance requirements.

Key Features of Thermoplastic Containment Basins

Unlike traditional concrete basins, thermoplastic designs offer superior adaptability:

- Custom manufacturing without dimensional limitations

- High resistance to chemical attack, UV exposure, and humidity

- Smooth internal surfaces for easy cleaning and inspection

- Modular construction, allowing the integration of ladders, gratings, or pump mounts

- Lightweight yet structurally stable, reducing installation costs

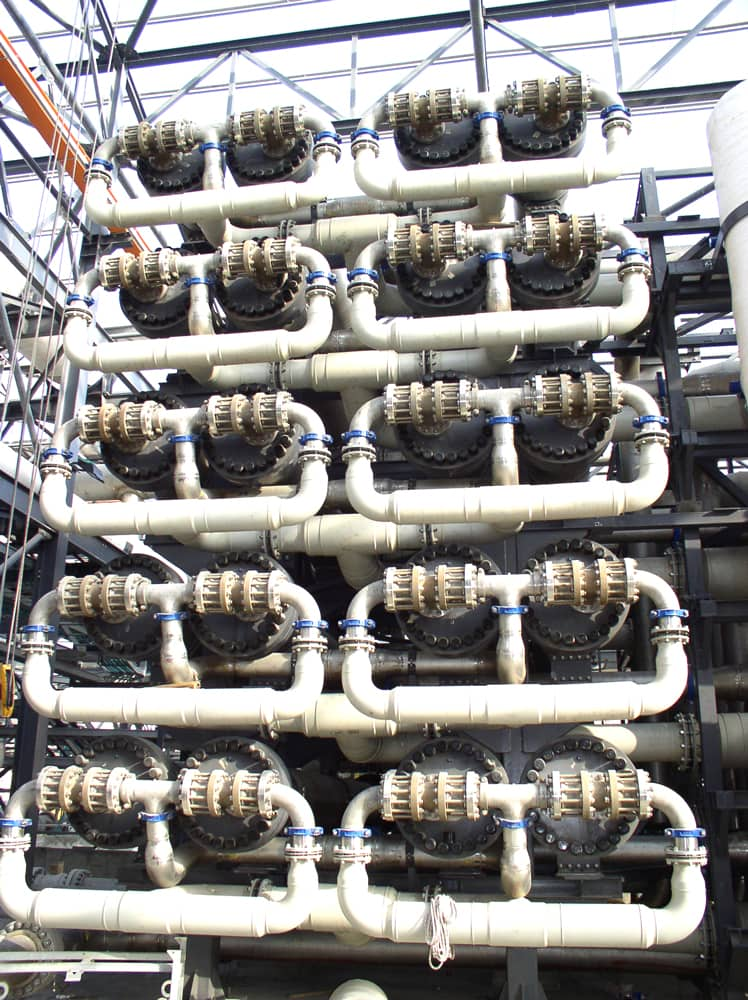

Integration with Industrial Systems

Containment basins are designed to work seamlessly with surrounding infrastructure. They are often combined with:

- Water circulation systems - ensuring proper drainage and controlled discharge

- Filtration and pumping systems - allowing safe removal of collected liquids

- Monitoring equipment - sensors and alarms for leak detection and compliance reporting

For added flexibility, internal mesh partitions made of PP or HDPE can be installed. These partitions help separate zones within the basin, regulate liquid flow, and adapt the structure for different operational needs.

Regulatory and Environmental Aspects

In most industrialized countries, containment basins are required by law whenever hazardous materials are stored. Regulations are driven by environmental protection agencies and health and safety authorities.

Key compliance points include:

- Ensuring basin capacity meets or exceeds the maximum volume of stored containers.

- Using materials resistant to the chemicals in use.

- Maintaining regular inspections and documented testing.

Failure to comply can result in significant fines, legal liability, and, in extreme cases, shutdown of operations.

Applications Across Industries

Containment basins are widely used in:

- Chemical industry - for acids, bases, solvents, and intermediate products.

- Fuel and energy facilities - for diesel, oils, and lubricants.

- Pharmaceutical and food processing - where hygiene and leak prevention are critical.

- Water treatment plants - for chlorine, coagulants, and other treatment chemicals.

Each application requires a tailored solution that considers the chemical profile, installation environment, and operational safety standards.

Advantages of Plastic and Fiberglass Basins

While concrete and steel basins still play a role in heavy industry, thermoplastic and fiberglass containment basins offer several distinct advantages:

- Superior chemical resistance compared to concrete

- No risk of corrosion, even in high-humidity environments

- Lower maintenance costs over the lifecycle

- Easier installation and relocation when required

- Longer service life with reduced operational risk

Conclusion

Containment basins are an essential component of safe and compliant industrial operations. While traditional concrete solutions remain in use, thermoplastic and fiberglass basins are increasingly chosen for their superior resistance to chemicals, durability, and cost-effectiveness.

By combining tailored engineering design with regulatory compliance, companies can ensure that their containment systems provide reliable protection for both people and the environment.