The Revolution in Industrial Tank Design

In recent decades, a true revolution has taken place in the design and production of industrial tanks. Thermoplastic and fiberglass (FRP) materials have become the preferred alternative to traditional metals such as steel or aluminum, combining mechanical strength, chemical resistance, lightweight structure, and nearly unlimited design flexibility.

At Plast Hen, Israel’s leading manufacturer of thermoplastic and fiberglass industrial tanks, hundreds of customized tanks and engineered solutions have been developed over the years. Each product is carefully designed according to site conditions, the chemical nature of the stored medium, and operational requirements - while meeting strict international standards and undergoing rigorous quality control throughout the manufacturing process.

1. Chemical Industry - Built for Aggressive Environments

One of the primary industries relying on thermoplastic and fiberglass tanks is the chemical sector, where durability and corrosion resistance are vital.

PP and PVDF tanks, for example, are used for storing sulfuric acid, sodium hydroxide, chlorine, ammonia, and other liquids with extreme pH levels. Thermoplastics are chemically inert, ensuring the purity of the stored material and a long service life.

FRP (Fiberglass Reinforced Plastic) tanks offer the ideal solution when a combination of mechanical strength and chemical resistance is required - such as in large-capacity tanks for fertilizer or energy production plants. The fiberglass exterior provides rigidity, while the internal thermoplastic liner (usually PP or PVC) protects against chemical reaction.

Example:

At a chemical facility in southern Israel, 40 m³ tanks were produced with a PP inner liner and FRP exterior shell - a combination that ensures full resistance to temperature fluctuations and internal pressure over time.

2. Water and Wastewater Treatment Applications

In water and wastewater treatment systems, thermoplastic tanks offer clear advantages: they do not corrode, they withstand oxidizing agents and chlorides, and they can be installed even in damp or corrosive environments.

Typical applications include:

- Process water and treated water storage

- Industrial wastewater collection

- Neutralization tanks before discharge to municipal systems

- Filtration and purification units with integrated channels and drainage points

In recent years, Plast Hen has developed dedicated solutions for dairy and industrial wastewater facilities, where thermoplastic tanks enable efficient chemical filtration and separation between solids and liquids.

3. Food and Pharmaceutical Industries - Maximum Hygiene and Safety

In sensitive industries such as food production, cosmetics, and pharmaceuticals, material purity and sterilization are key. Thermoplastic tanks - with their smooth, non-absorbent surfaces - are ideal for clean, hygienic environments.

Common uses include:

- Storage of syrups, mild acids, and solutions in pharmaceutical manufacturing

- RO water and process water tanks for pharmaceutical systems

- Mixing, homogenization, and transport of clean liquids

Tanks made of PP, HDPE, FRP, and PVDF are often installed within closed production systems, featuring gas inlet ports or CIP (Cleaning In Place) fittings for sterile maintenance.

When thermal protection is required - such as in hot water storage - insulated tanks are used to maintain a stable temperature throughout the process.

4. Agricultural and Aquaculture Applications

In agriculture and aquaculture, thermoplastic and fiberglass tanks play an essential role due to their high resistance to outdoor conditions.

- In agriculture: tanks are used for irrigation systems, fertilizer mixing, water storage, and disinfection fluids.

- In aquaculture: cylindrical PP or HDPE tanks serve as fish-rearing basins, offering UV protection and saltwater resistance.

FRP tanks are ideal for high-density fish farming, combining structural strength with smooth surfaces that simplify cleaning and maintenance. Plast Hen has developed a wide range of systems in this field, including fish breeding pools, marine cages, and advanced drainage systems.

5. Energy and Petrochemical Industries - Maximum Structural and Chemical Resistance

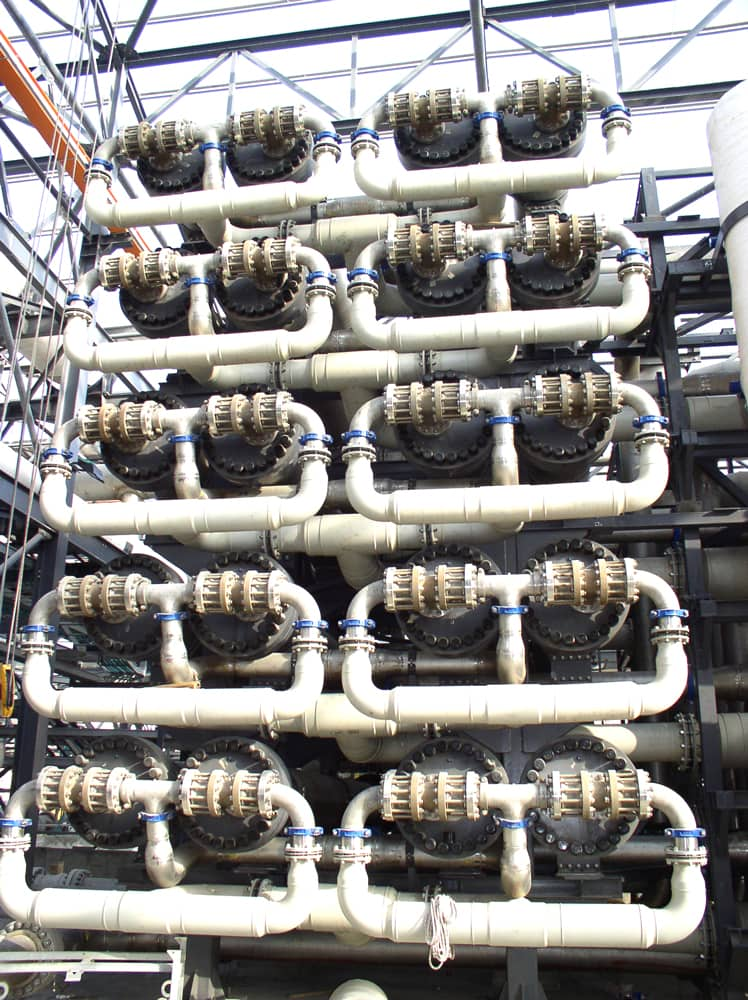

In petrochemical and energy applications, thermoplastic tanks such as PP or HDPE provide reliable containment for fuels, oils, and highly reactive compounds. These tanks are commonly installed in storage facilities, power stations, and refineries - often as part of closed systems with compatible thermoplastic piping.

Hybrid tanks - such as PP/FRP or PVDF/FRP - maintain structural stability under high pressure. For volatile liquids or solvents, anti-static layers and controlled ventilation are added to prevent gas buildup and ensure operational safety.

6. Key Advantages of Thermoplastic and Fiberglass Tanks

The engineering benefits of these materials place them at the forefront of modern industrial design:

🗸 Exceptional chemical and physical resistance - consistent performance under extreme conditions.

🗸 High structural strength with low weight - easy handling, transport, and installation.

🗸 Flexible design options - cylindrical, conical, rectangular, or horizontal structures.

🗸 Zero corrosion - no coating or periodic maintenance required.

🗸 Long-term cost efficiency - minimal maintenance and a lifespan of 20-30 years.

🗸 Environmental responsibility - recyclable materials that comply with ISO and EPA standards.

7. Quality Control and Engineering Precision

At Plast Hen, every tank is engineered and manufactured under strict quality control. The process includes:

- Design according to the DVS 2205 standard

- Full 3D modeling before production

- Mechanical, thermal, and pressure resistance testing

- Custom adaptation to site-specific parameters - temperature, humidity, soil type, and stored medium

The combination of advanced welding techniques, precision design, and over three decades of engineering expertise enables the production of highly reliable tanks that meet the most demanding international standards.

Conclusion - Smart Engineering Driving Industrial Progress

Thermoplastic and fiberglass tanks are no longer just an alternative to steel - they define a new industrial standard for strength, efficiency, and sustainability.

Through precise engineering, advanced production technologies, and a personalized approach to every project, Plast Hen continues to deliver solutions that power the core of modern industry - from chemical plants to advanced water treatment facilities.

The synergy between knowledge, materials, and technology allows for long-lasting, high-performance systems that prove time and again that choosing the right material means choosing long-term value.