Industrial processes that involve aggressive chemicals, high temperatures, or strict purity requirements demand storage and process tanks that can withstand extreme conditions. Among the most advanced solutions are PVDF (Polyvinylidene Fluoride) and ECTFE (Ethylene Chlorotrifluoroethylene, known commercially as Halar®) tanks.

These fluoropolymer-based tanks provide superior chemical resistance, exceptional temperature tolerance, and long service life, making them ideal for sectors such as chemical processing, semiconductors, pharmaceuticals, biotechnology, and water treatment. When combined with FRP (Fiberglass Reinforced Plastic) shielding, they offer both chemical durability and high mechanical strength.

PVDF Tanks - Reliability Under Extreme Conditions

PVDF tanks are widely recognized for their outstanding resistance to acids, bases, and salts. They perform reliably at continuous service temperatures up to 140°C and can tolerate short peaks up to 150°C. PVDF is hydrophobic, does not absorb moisture, and maintains its structural integrity under UV exposure, making it suitable for both indoor and outdoor installations.

Applications include storage of concentrated hydrochloric acid, sulfuric acid, and high-purity water in semiconductor and pharmaceutical plants. PVDF’s smooth, non-stick surface is also ideal for sterile or cleanroom environments where contamination must be minimized.

ECTFE Tanks - Superior Resistance to Oxidizing Agents

ECTFE, or Halar®, is another high-performance fluoropolymer designed to withstand particularly aggressive oxidizing agents such as nitric acid, chlorine, and sodium hypochlorite. It offers continuous service up to 150°C and peaks of 160°C.

Compared to PVDF, ECTFE provides enhanced mechanical strength and improved long-term performance in environments where oxidizers are present. This makes it highly suitable for applications in chlor-alkali plants, gas treatment facilities, and advanced wastewater treatment.

FRP Shielding - Hybrid Structural Reinforcement

While PVDF and ECTFE provide superior chemical resistance, they are thermoplastics with moderate mechanical strength. To address this, tanks are often reinforced with FRP (Fiberglass Reinforced Plastic) jackets.

This hybrid design combines the chemical protection of the fluoropolymer with the structural strength of fiberglass. The FRP layer supports the tank under pressure, external loads, or when installed outdoors. Custom FRP reinforcement can be engineered according to project requirements, ensuring durability and safety even in harsh industrial environments.

Typical Industrial Applications

- Chemical industry - storage of strong acids, bases, and oxidizing agents

- Semiconductors and electronics - ultra-pure water and chemical baths requiring strict cleanliness

- Pharmaceuticals and biotechnology - sterile processes and high-purity fluids

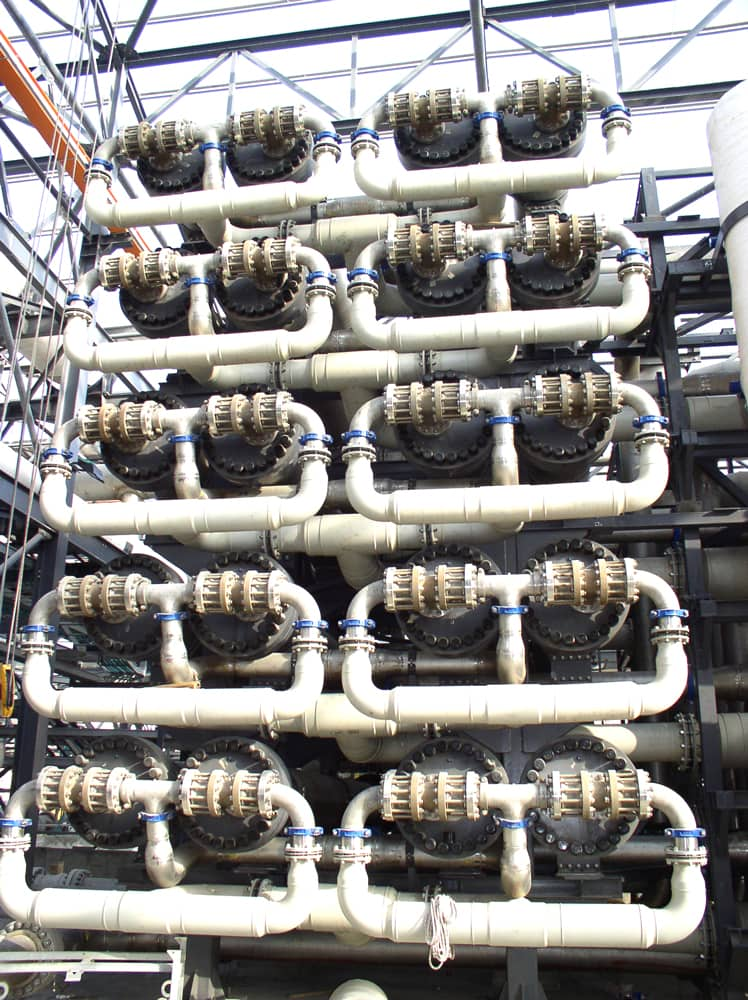

- Water treatment and desalination - handling aggressive brines and disinfection chemicals

- Outdoor installations - where UV exposure, wind loads, and temperature variations must be considered

Technical Comparison Table

| Parameter | PVDF (Polyvinylidene Fluoride) | ECTFE (Ethylene Chlorotrifluoroethylene) |

|---|---|---|

| Continuous Service Temp. | up to 140°C | up to 150°C |

| Short-Term Peak Temp. | up to 150°C | up to 160°C |

| Resistance to Strong Acids | Excellent (H₂SO₄, HCl) | Excellent incl. oxidizers (HNO₃, Cl₂) |

| Resistance to Bases | Excellent | Excellent |

| Resistance to Oxidizers | Good | Excellent |

| Moisture Absorption | None | None |

| UV Resistance | High | High |

| Mechanical Strength | Medium | Higher than PVDF |

| Specific Gravity | ~1.78 g/cm³ | ~1.68 g/cm³ |

| FRP Reinforcement Option | Yes | Yes |

| Typical Service Life | 25-30 years | 25-35 years |

| Certifications | FDA, USP Class VI, ISO | FDA, USP Class VI, ISO |

Advantages of PVDF & ECTFE Tanks

- Exceptional chemical resistance against acids, bases, and oxidizers

- High temperature tolerance for continuous operation

- Smooth, non-stick surface that prevents buildup and contamination

- UV-resistant, suitable for outdoor installations

- Custom FRP reinforcement for structural strength and pressure handling

- Long service life with minimal maintenance requirements

Conclusion

PVDF and ECTFE tanks represent the highest standards in chemical storage and process safety. With their unmatched chemical resistance, high temperature capabilities, and long service life, they provide reliable solutions for industries facing aggressive environments. When reinforced with FRP, these tanks offer both durability and structural integrity, ensuring safety and performance even under the toughest conditions.

For engineers and decision-makers, selecting PVDF or ECTFE tanks is not just about meeting today’s needs-it’s about securing long-term reliability and compliance for critical industrial processes.