In many industrial sectors, there is a growing demand for tanks that combine high thermal resistance, broad chemical durability, and long-term structural stability. Polypropylene (PP) tanks are an ideal solution, offering exceptional performance in challenging environments where contact with strong acids, bases, and aggressive chemicals occurs - even at medium to high temperatures.

At Plast Hen, we specialize in the design and manufacturing of PP tanks based on precise engineering specifications, strict quality standards, and professional technical support throughout the entire process.

Key Features and Advantages of PP Tanks

Polypropylene tanks are widely regarded as one of the most effective and reliable solutions for industrial applications thanks to their unique properties:

- High thermal resistance - suitable for continuous operation at temperatures up to 90°C.

- Extensive chemical resistance - effective against acids, bases, and other aggressive substances.

- Structural stability - maintains strength even under load and in fluctuating temperatures.

- Lightweight construction - easy to install, handle, and transport compared to metal alternatives.

- Smooth interior surface - prevents contaminants, deposits, and residues from adhering, making cleaning and maintenance easier.

Main Applications of Polypropylene Tanks

Thanks to their versatility and performance, PP tanks are used across a wide range of industries:

- Water and wastewater treatment - durable storage and processing of aggressive liquids.

- Thermal production processes - storage of active materials exposed to higher temperatures.

- Pharmaceuticals and biotechnology - handling chemicals in controlled production environments.

- Food industry - safe storage of sensitive ingredients and additives in sterile conditions.

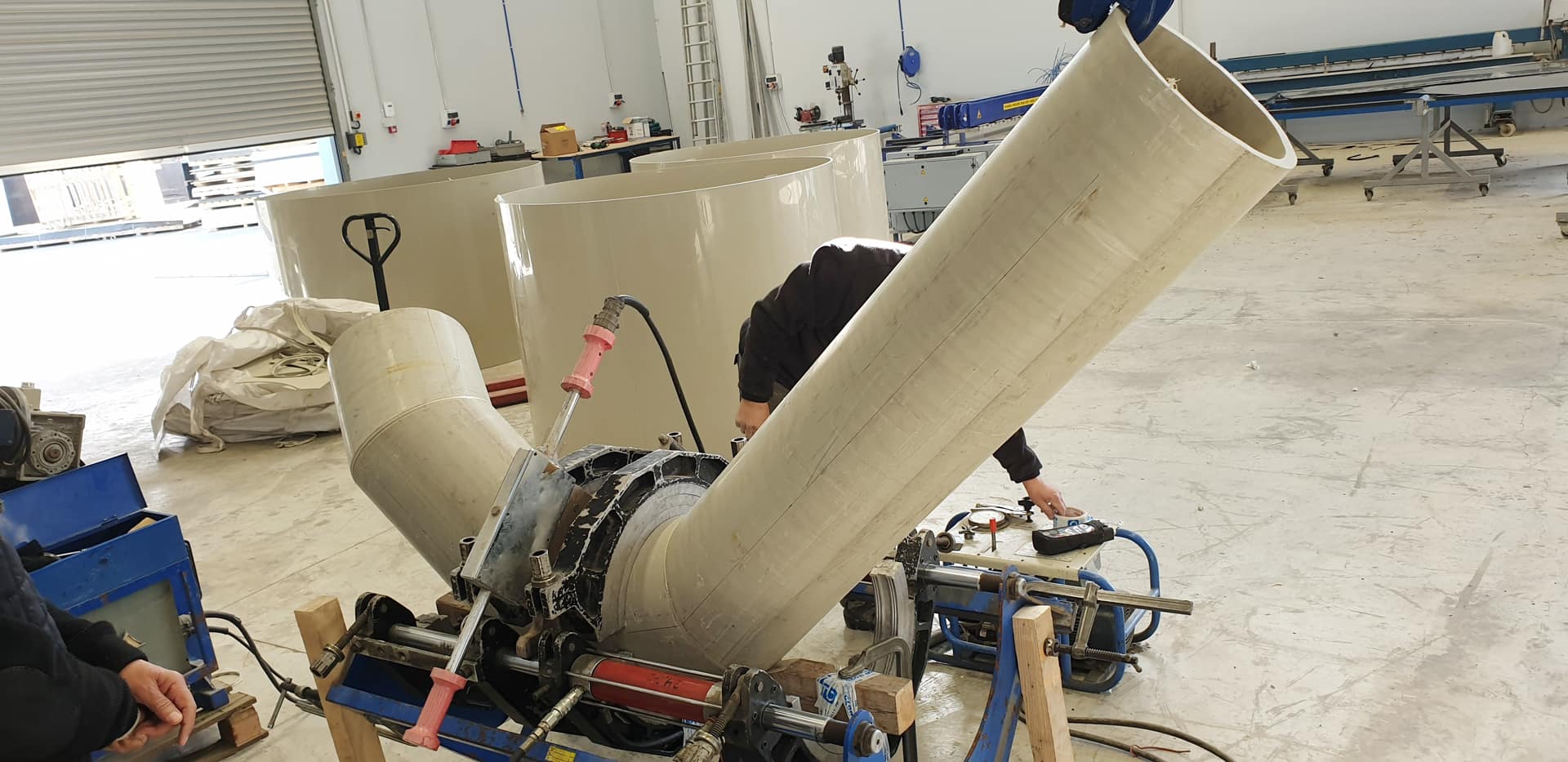

Design Flexibility and Custom Options

At Plast Hen, PP tanks can be manufactured in different configurations to suit specific requirements:

- Cylindrical or rectangular structures - adapted to the available space and application.

- Vertical or horizontal orientation - depending on operational needs.

- Flat or conical bottoms - for efficient liquid and solid discharge.

- Custom installations - service openings, connections, ladders, railings, strainers, and drainage systems.

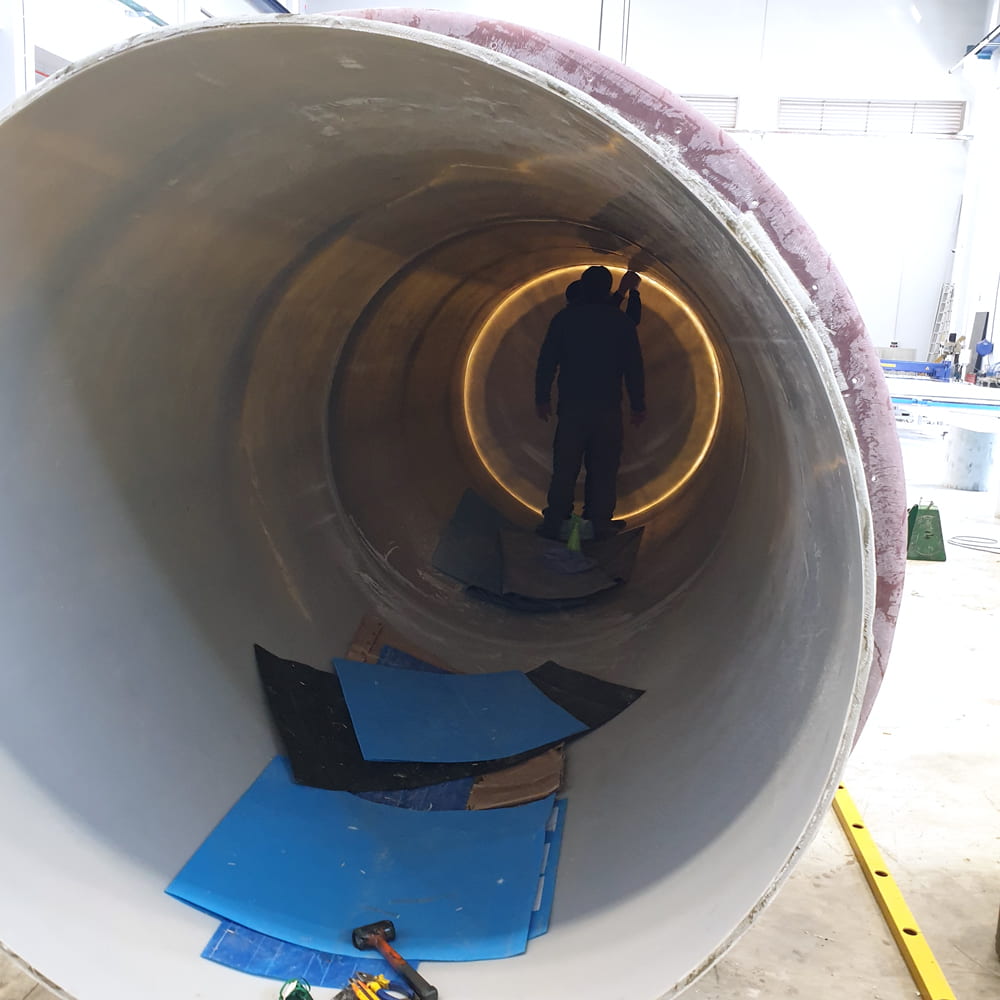

FRP Reinforcement - Additional Strength for PP Tanks

For applications that demand extra structural reinforcement - such as high pressures, large volumes, or outdoor environments - PP tanks can be equipped with an external FRP (Fiberglass Reinforced Plastic) layer.

This hybrid solution combines the best of both worlds:

- The inner PP structure ensures full chemical resistance.

- The FRP outer layer provides additional structural strength and durability.

- Extended service life and reliability, even in harsh industrial environments.

Quality Assurance and Standards

All PP tanks manufactured by Plast Hen undergo a rigorous quality control process. From 3D computer-aided design, through the use of high-grade raw materials, to mechanical and chemical resistance testing - every tank is built to comply with the strictest international and Israeli standards. This ensures a reliable, safe, and long-lasting solution for every industrial need.

Conclusion

Polypropylene tanks are the preferred choice for industries requiring thermal and chemical resistance, lightweight design, and structural reliability. With customized configurations and optional FRP reinforcement, they provide precise engineering solutions tailored to demanding industrial applications.

At Plast Hen, we guide our clients every step of the way - from design to installation - ensuring a professional, safe, and durable solution that delivers outstanding performance for years to come.