About Plastic Pipe Welding

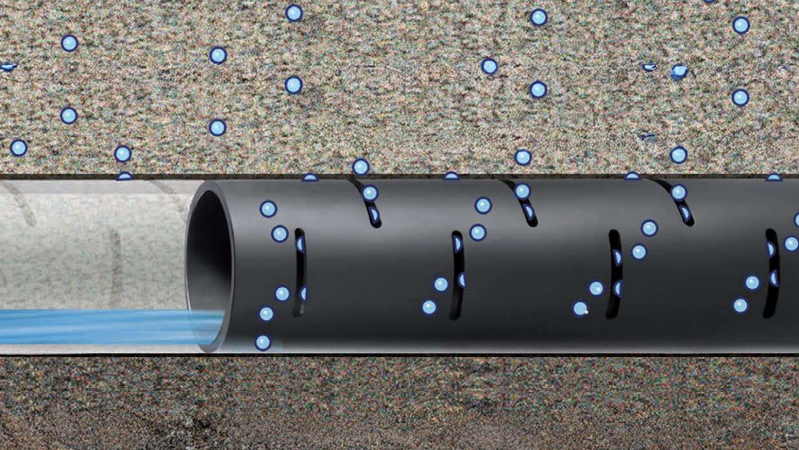

Plastic piping has become the leading solution in recent years across water infrastructure, sewage, drainage, gas, and chemical industries, thanks to its clear advantages over metal piping: high resistance to corrosion, lightweight design, flexibility in planning, and quick installation.

However, to ensure a reliable, safe, and long-lasting piping system, the use of professional welding equipment is essential, tailored to the specific type of pipe and project requirements.

Types of Plastic Pipes for Welding

At Plast Hen, we specialize in welding a wide range of thermoplastic pipes, including:

- HDPE (High-Density Polyethylene) piping - ideal for water systems, sewage, and heavy industry.

- PP (Polypropylene) piping - suitable for hot water, steam, and chemical processes.

- PVC piping - a common solution for drainage, sewage, and food industries.

- PVDF piping - designed for aggressive chemical environments and high-temperature applications.

Expertise in Large Diameters - Up to 800 mm and Beyond

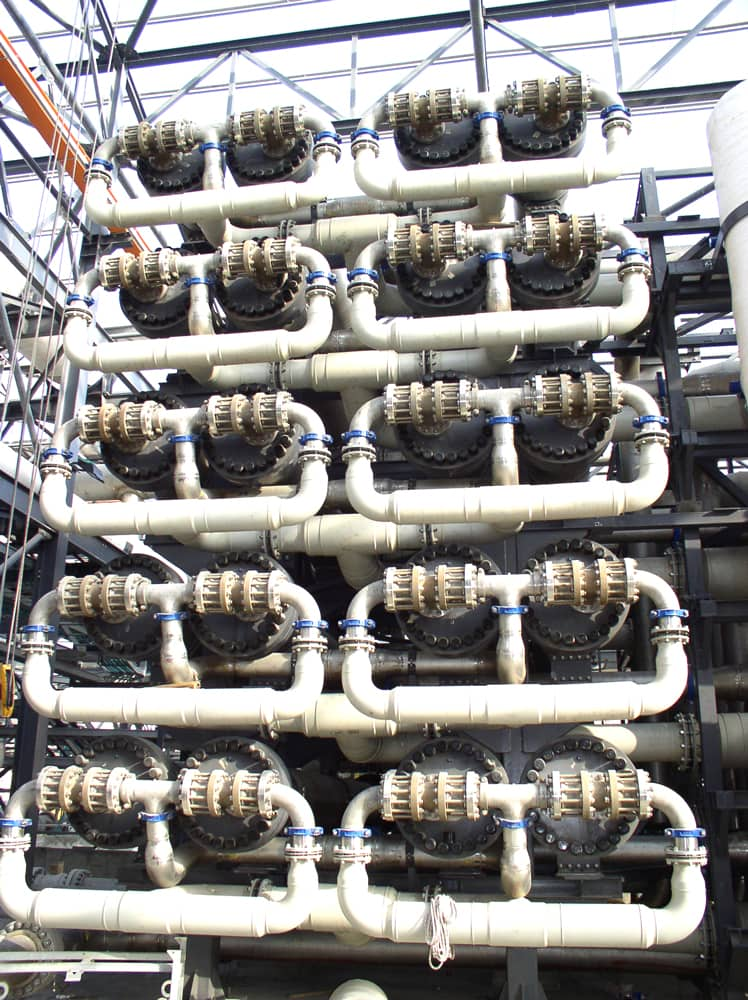

We specialize in welding pipes up to 800 mm in diameter using the Butt Welding (B.W.) method - a precise technique that creates a strong, uniform, and long-lasting connection.

For extra-large diameters above 800 mm, we employ Extrusion Welding, which enables strong and efficient connections even in highly complex piping systems.

Advanced Welding Methods

We use some of the world’s most advanced plastic pipe welding machines, operating with different technologies:

- Butt Welding (B.W.) - ideal for medium to large diameters, ensuring complete sealing and high mechanical strength.

- Extrusion Welding - suitable for very large diameters or complex structural connections.

- Electrofusion Welding - designed specifically for HDPE connections, using electrical fusion for reliable bonding.

Why Choose Plast Hen?

- Over 33 years of experience in welding thermoplastic pipes and tanks.

- Proven ability to handle complex industrial projects of any scale.

- Use of advanced welding equipment that guarantees quality, precision, and safety.

- Comprehensive service - from engineering consultation to full on-site execution.

Conclusion

Plastic pipe welding requires professional expertise, the right equipment, and specialization in large diameters. At Plast Hen, we provide advanced welding solutions for HDPE, PP, PVC, and PVDF pipes - up to 800 mm using the Butt Welding method, and beyond with Extrusion Welding.

The result: reliable, safe, and durable piping connections designed to perform for years to come.