Introduction to Advanced Plastic Manufacturing Processes

The plastic manufacturing industry in Israel has undergone a significant technological revolution in recent decades. Modern plastic manufacturing plants no longer focus solely on mass production of standard products but specialize in developing complex, customized solutions for various industries.

A plastic factory like Plast Chen, operating in Israel for over 30 years, implements advanced thermoplastic manufacturing processes that combine precise engineering design, selection of advanced materials, and innovative production technologies that ensure quality and durability over time.

Advanced Technologies in Plastic Product Manufacturing

Digital Design and 3D Modeling

The digital revolution has fundamentally changed the design and development processes in plastic factories. Advanced CAD (Computer-Aided Design) software allows engineers to design complex products with maximum precision, perform simulations of mechanical loads, and examine material behavior under various conditions before production begins.

In plastic production facilities like Plast Chen, advanced CAD software is used for the design and calculation of products that meet the stringent German DVS 2205 standard, enabling the production of thermoplastic containers with maximum durability and safety.

Innovative Manufacturing Methods

In recent years, several innovative plastic manufacturing techniques have been developed in the industry:

- Precision Injection Molding: Technology that enables the production of complex parts with high precision while efficiently using raw materials.

- Rotational Molding: A method suitable for producing large, hollow containers, allowing products with uniform wall thickness.

- Advanced Extrusion: For producing profiles, pipes, and sheets with high precision.

- CNC Welding: Enables joining plastic parts with maximum precision, with computerized control of all welding parameters. In advanced plastic manufacturing plants like Plast Chen, unique CNC equipment enables production of detailed printing for examining welding quality.

- CNC Machining: For precise processing of complex plastic parts with tight tolerances.

Advanced Materials in the Plastic Industry

Engineering Polymers

Advanced industries require engineering polymers with special properties. A professional plastic factory like Plast Chen specializes in working with a variety of materials:

- High-Density Polyethylene (HDPE): Chemical-resistant, rigid material with high mechanical strength, used for manufacturing containers, pipes, and industrial products.

- Polypropylene (PP): A Polymer with good chemical resistance and high mechanical strength, suitable for a wide range of applications.

- Polyvinyl Chloride (PVC): Fire-resistant material with good electrical properties, used for manufacturing pipes, accessories, and industrial products.

- Polyvinylidene Fluoride (PVDF): Advanced polymer with exceptional resistance to aggressive chemicals, used in the chemical, pharmaceutical, and food industries.

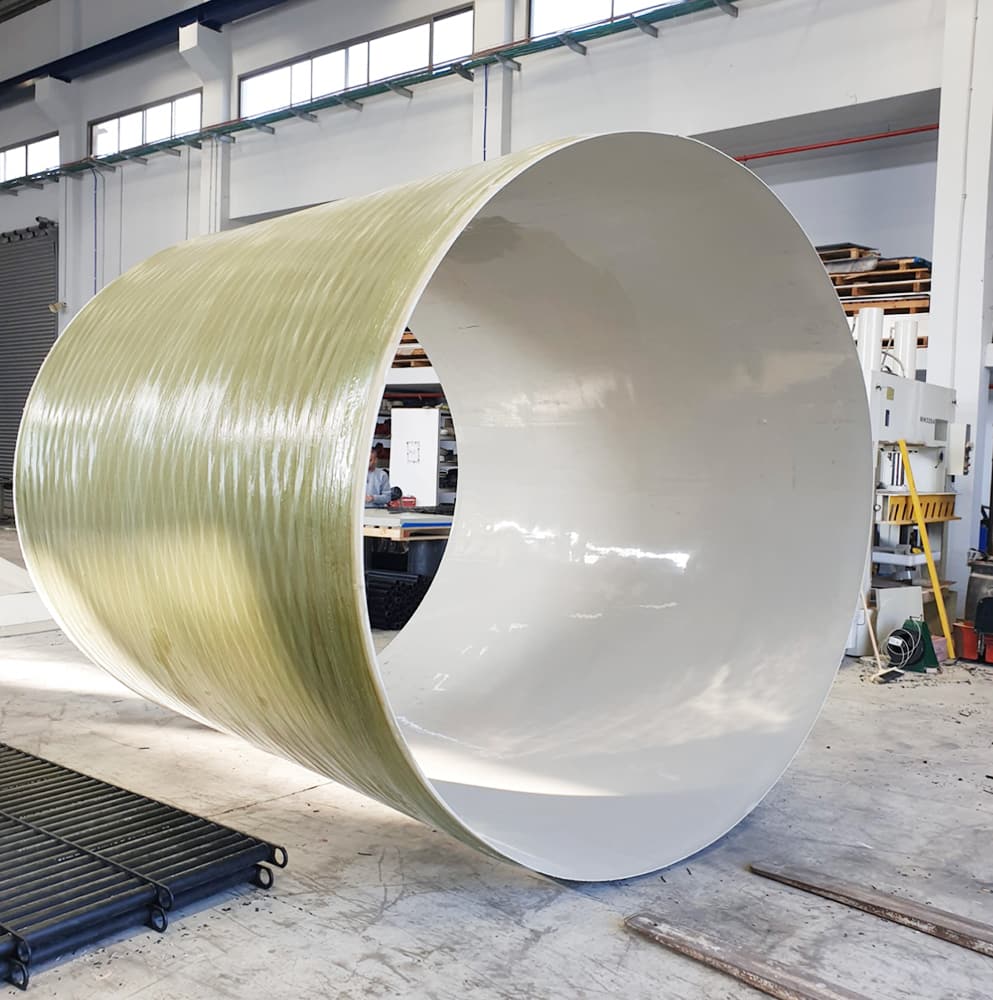

- Composite Materials (FRP): A Combination of polymers with glass fibers or other materials, providing exceptionally high mechanical strength.

Custom Manufacturing and Made-to-Order Production

One of the most developing areas in the plastic industry is custom plastic production. Unlike mass production, custom orders allow clients to receive products precisely tailored to their unique needs.

Customized Development and Manufacturing Process

The process of developing a custom plastic product in a professional plastic product factory includes several stages:

- Requirements Specification: Deep understanding of client needs, operational environment, and technical requirements.

- Engineering Design: Detailed product design, including selection of appropriate materials and design optimization.

- Simulation and Prototyping: Creation of computerized simulations and prototypes to test fit and function.

- Production Process Planning: Selection of appropriate manufacturing method and optimization of parameters.

- Manufacturing: Production with rigorous quality control.

- Testing and Approval: Testing the final product to ensure compliance with all requirements.

Case Study: Advanced Applications in the Chemical Industry

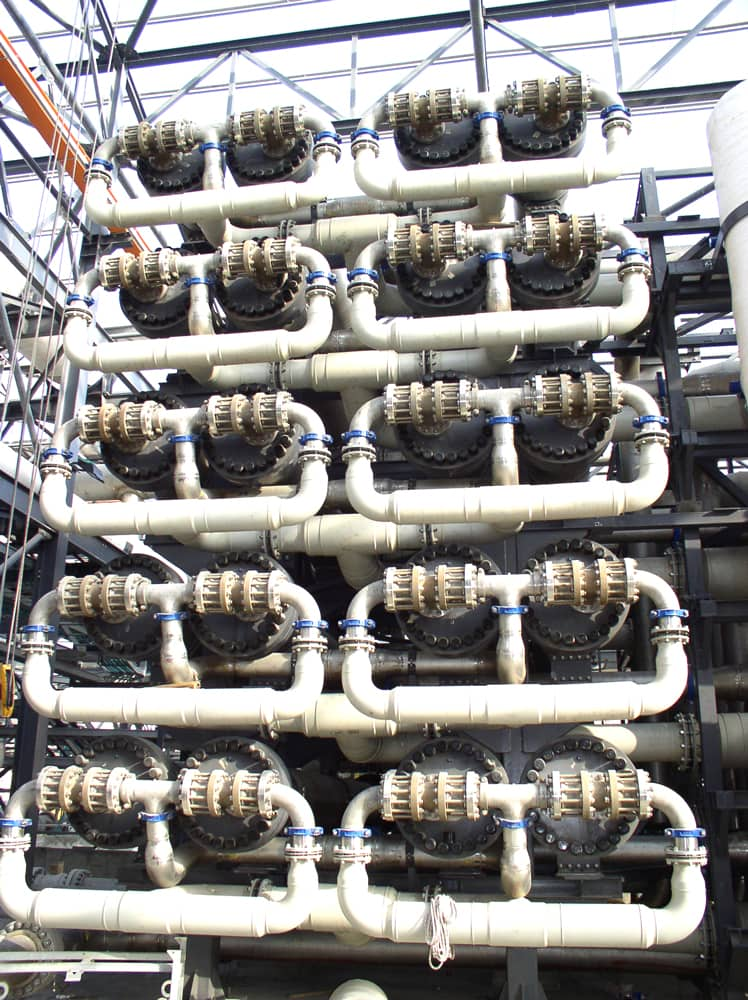

The chemical and petrochemical industry provides an excellent example of the use of advanced plastic products. At chemical industry sites such as Dead Sea Works, plastic products with high resistance to aggressive chemicals, extreme temperatures, and high pressures are required.

Plast Chen, as a leading plastic manufacturing plant in the field, has supplied unique solutions to chemical plants in Israel and abroad over the years, including:

- High-resistance chemical storage containers

- Pipes and pipe fittings for transporting hazardous materials

- Advanced filtration and protection systems

- Equipment for chemical production processes in extreme conditions

Solutions for Diverse Sectors

Water and Energy Industry

The water and energy industry makes extensive use of advanced plastic products. Plastic manufacturing plants provide solutions such as:

- Piping systems for water, sewage, and effluent transport

- Balancing and storage tanks

- Filtration and control systems

- Components for desalination and wastewater treatment facilities

A professional plastic products factory can design and manufacture solutions tailored to the unique challenges of these industries, while meeting the most stringent standards.

Marine and Conventional Agriculture

Modern agriculture relies on advanced plastic solutions. Plast Chen, for example, has gained extensive experience in plastic manufacturing for marine agriculture in Israel and abroad, providing solutions such as:

- Irrigation and drip systems

- Advanced design fish ponds

- Custom aquaculture facilities

- Storage and transport containers with innovative technology

Food and Pharmaceutical Industries

These industries require plastic products that meet stringent standards. Custom plastic manufacturing enables the supply of solutions such as:

- Containers and storage systems in sterile conditions

- Equipment for pharmaceutical and food production processes

- Transport and filtration systems

- Special containers and packaging

Sustainability and Innovation in the Plastic Industry

Recycling and Waste Reduction

One of the significant challenges in the plastic industry is reducing environmental impact. Modern plastic manufacturing plants implement advanced methods for reducing waste and recycling.

Plast Chen, for example, implements a responsible approach to sustainability: each year, approximately 30 tons of raw material residues accumulate in the plastic manufacturing process, and the company ensures they are ground and transferred for recycling, so the material is returned for use in other plastic industries - an example of environmental responsibility in the industry.

Compliance with Standards and Quality Control

International Standards

A quality plastic factory operates according to stringent international standards:

- ISO 9001: Quality management standard, ensuring organized work processes and consistent quality.

- DVS 2205: Stringent German standard for design and production of thermoplastic containers.

- FDA Standards: For materials in contact with food and pharmaceuticals.

Leading factories like Plast Chen adhere to these standards and even set a higher bar for themselves to ensure the quality of products and service to their customers.

Summary: How to Choose a Professional Plastic Factory

When selecting a plastic products factory for an industrial project, several factors should be considered:

- Experience and Longevity: A veteran plastic factory like Plast Chen, with decades of experience, brings accumulated knowledge and experience in solving complex challenges.

- Technological Capabilities: It's important to choose a facility equipped with the most advanced design and production technologies.

- Specialization in Advanced Materials: Plastic manufacturing plants specializing in a wide range of materials can offer the optimal solution for any application.

- Flexibility and Custom Plastic Manufacturing: The ability to develop and produce products precisely tailored to specific requirements is a significant advantage.

- Standards Compliance: A facility that meets stringent international standards ensures quality and reliability.

- Environmental Responsibility: Choosing a facility committed to sustainability and reducing environmental impact reflects corporate responsibility values.