HDPE (High-Density Polyethylene) Tanks - A Durable, Safe, and Versatile Industrial Solution

In today’s industrial landscape, there is a constant demand for reliable storage solutions that combine high durability, lightweight design, and minimal maintenance. This is exactly what HDPE (High-Density Polyethylene) tanks provide. Recognized as one of the most popular tank types worldwide, HDPE tanks offer the perfect balance of mechanical strength, chemical resistance, and customization flexibility.

HDPE is a high-density thermoplastic polymer known for its resistance to abrasion, corrosion, UV radiation, and extreme temperatures. These properties make HDPE tanks ideal not only for the chemical industry, but also for the food, agriculture, and environmental sectors.

Why Choose HDPE?

The uniqueness of HDPE tanks lies in their combination of rare physical and chemical advantages:

- Broad chemical resistance - suitable for storing acids, bases, and corrosive solutions.

- Impressive structural strength - maintains stability under pressure and large volumes; resistant to cracks and impacts.

- Lightweight design - easier to transport, install, and operate compared to metal alternatives.

- Environmental durability - does not rust, degrade, or absorb moisture; suitable for long-term outdoor use.

- Low maintenance - requires no special coatings, frequent treatments, or protective layers.

Common Applications of HDPE Tanks

Thanks to their versatility, HDPE tanks are widely used across industries:

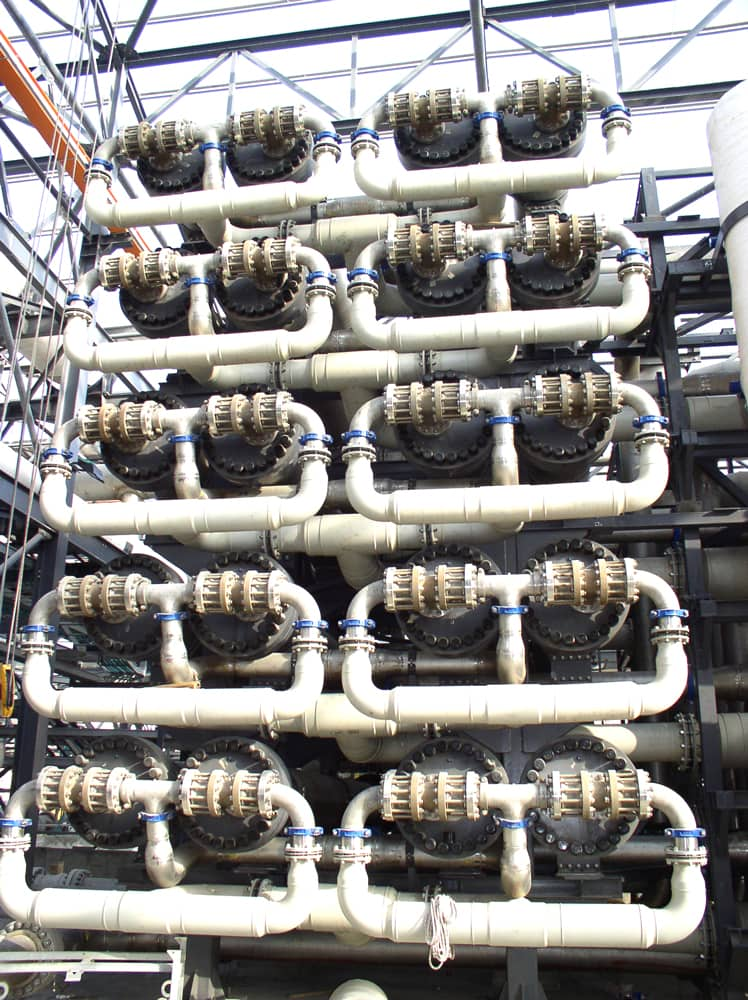

- Water and wastewater treatment - storage and handling of liquids in municipal and industrial systems.

- Chemical and pharmaceutical industries - processing and storing active materials, solvents, and bases.

- Food and agriculture - storage of clean liquids, food additives, raw materials, and fertilizers.

- Environmental and green industries - liquid storage under variable and extreme conditions.

Design Options and Customization

One of the greatest advantages of HDPE tanks is their design flexibility, allowing full adaptation to project-specific requirements:

- Cylindrical or rectangular structures - selected based on capacity and installation area.

- Vertical (standing) tanks - space-saving, ideal for narrow or confined locations.

- Horizontal (lying) tanks - perfect for underground installations or mobile applications.

- Flat bottom - standard solution for general storage.

- Conical/sloped bottom - enables fast and efficient drainage of liquids and solids.

- Custom fittings and accessories - service openings, mixing systems, pipelines, ladders, railings, platforms, drainage channels, and more.

Precision Manufacturing and Quality Standards

At Plast Hen, we specialize in the production of custom HDPE tanks, engineered with precision and manufactured under strict quality control. Our production process involves advanced cutting, welding, and assembly technologies, with every stage supervised by our expert engineering team.

All tanks are manufactured in compliance with international standards, ensuring safe, reliable, and long-term operation - even in the most challenging environments.

Conclusion

HDPE tanks provide a versatile, durable, and safe solution for the storage of liquids, chemicals, and raw materials. With their unique combination of strength, lightweight design, chemical resistance, and endless customization options, they represent a smart choice for industrial plants, water companies, food production, and agriculture.

At Plast Hen, we combine decades of expertise, advanced technology, and uncompromising quality to deliver HDPE tanks tailored to your project needs - with full professional support from design through on-site installation.