In today’s industrial world, companies need storage solutions that combine exceptional mechanical strength with outstanding chemical resistance. That’s exactly what FRP (Fiberglass Reinforced Plastic) tanks deliver.

Made from a composite material of polymers reinforced with fiberglass, FRP tanks are engineered to withstand heavy loads, aggressive chemicals, and extreme environmental conditions. Their multi-layered structure and fiberglass reinforcement ensure stability and long-term performance, even in the most challenging industrial environments.

Despite their strength, FRP tanks are relatively lightweight, making transportation, installation, and handling much easier compared to metal alternatives.

Where Are FRP Tanks Used?

Thanks to their durability and versatility, FRP tanks are widely used across multiple industries:

- Storage of liquids in the chemical and petrochemical sectors.

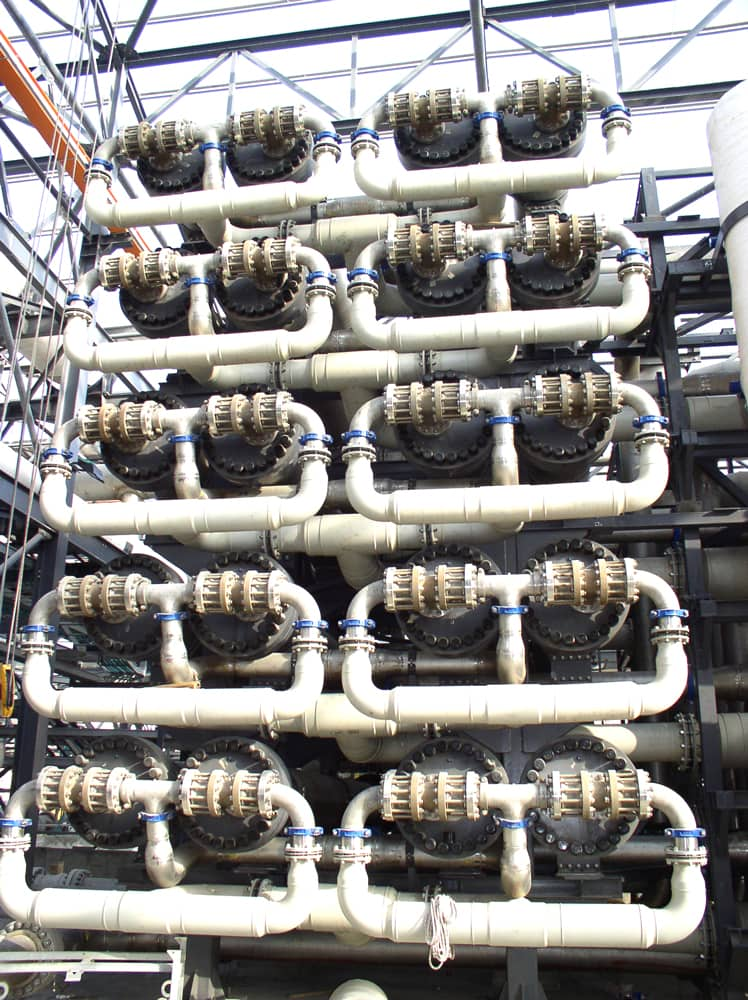

- Wastewater treatment plants and industrial water systems.

- Handling of salts, heavy solutions, and gases.

- Agricultural and environmental facilities exposed to harsh climates.

Wherever strength, safety, and long-term reliability are required, FRP tanks are the right solution.

Key Advantages of FRP Tanks

FRP tanks stand out for their ability to combine structural performance with flexibility of design:

- High mechanical strength - even in large volumes and tall structures.

- Excellent chemical resistance - reliable performance against acids, bases, salts, and aggressive solutions.

- Long service life - they do not corrode, rust, or deteriorate over time.

- Lightweight construction - easy to transport and install despite their size.

- Thermal insulation - naturally suitable for outdoor applications.

Tailored Design and Advanced Solutions

One of the greatest benefits of FRP tanks is their design flexibility. They can be manufactured in cylindrical or customized shapes, vertical or horizontal layouts, with flat or conical bottoms for efficient drainage.

Additional features such as service openings, piping connections, ladders, railings, and safety platforms can be integrated according to project requirements.

For applications that demand even greater structural strength - such as high pressures, very large volumes, or outdoor installations - FRP can also be applied as an external reinforcement layer for thermoplastic tanks (PP or PVDF). This hybrid solution preserves the chemical resistance of the inner thermoplastic while adding superior external strength.

Quality and Engineering Excellence

At Plast Hen, every FRP tank is designed with precision engineering, manufactured under strict international standards, and tested with comprehensive quality control at every stage. Our clients benefit from full professional support - from design and planning to on-site installation - ensuring a safe, reliable, and high-performing tank for years to come.

Conclusion

FRP tanks are more than just storage vessels - they are a long-term investment in reliability and safety. With their combination of structural strength, chemical resistance, and thermal insulation, FRP tanks are ideal for almost any industrial application.

By choosing Plast Hen, you gain access to cutting-edge FRP solutions, tailor-made for your needs, with uncompromising quality and full peace of mind.