Advantages of Fiberglass in Height Safety

Working at height presents significant risks across various industrial environments, with falls ranking among the leading causes of serious workplace accidents. Fixed ladders with safety cages represent one of the most essential safety solutions that enable secure access to elevated locations while minimizing fall risks. Plast Hen specializes in manufacturing fiberglass (FRP - Fiberglass Reinforced Plastic) ladders with safety cages, combining maximum safety with unique advantages not available in traditional materials.

The choice of fiberglass is deliberate. This material offers an ideal combination of structural strength, resistance to harsh environmental conditions, and electrical properties particularly suited to diverse industrial environments. In recent years, with increasing safety awareness and regulatory requirements, Plast Hen's fiberglass ladders have emerged as an advanced solution that meets all current standards and requirements.

Regulatory Requirements in Israel and Worldwide

The Israeli requirements for fixed ladders and safety cages are established in the Occupational Safety Regulations (Work at Height), 2007. According to these regulations, fixed ladders without safety cages are permitted up to a height of 6 meters, while ladders with safety cages are allowed up to 10 meters. Above 10 meters, additional protection systems beyond the cage are required. The safety cage must begin approximately 2 meters from the ladder base and extend to its top, with rest platforms required at maximum intervals according to the total height.

Internationally, there is significant variation in standards. The British standard (BS 4211) is the most stringent, requiring safety cages from a height of just 2.5 meters, while the European standard (EN ISO 14122-4) requires fall protection from 3 meters, and the Australian standard (AS 1657) resembles the Israeli one with requirements from 6 meters. In the United States (OSHA), the requirement begins at 7.3 meters, but a revolutionary change has occurred: since November 2018, the American standard no longer recognizes safety cages as sufficient safety measures for new installations, requiring personal fall arrest systems or ladder safety systems, with a transition period until 2036.

Plast Hen designs its fiberglass ladders to meet the most stringent standards, with precise adaptations to regulatory requirements for each region and application.

Plast Hen's Fiberglass Ladders: Unique Advantages

Fiberglass ladders from Plast Hen offer significant advantages over ladders made from traditional materials like steel or aluminum. Fiberglass is a composite material that combines glass fibers within a polymeric resin, creating an exceptionally strong structure with unique properties. The ladders are manufactured with 50% fiber content within polyester or vinyl ester resin systems, ensuring excellent durability and longevity.

The most prominent characteristic of fiberglass ladders is their electrical non-conductivity, a critical advantage in environments with electrical hazards. They require no grounding and completely eliminate risks of electromagnetic interference or electrocution. Their broad chemical resistance, proven since the 1950s in the petrochemical industry, makes them ideal for aggressive industrial environments.

Plast Hen's fiberglass ladders come with a Class 1 fire rating, with flame spread below 25, and are equipped with UV-protected layers ensuring a lifespan exceeding 50 years even in harsh outdoor conditions. In addition to their lightweight nature, which allows for easier installation, they require almost no maintenance throughout their lifetime, resulting in low total ownership costs despite the higher initial investment.

Technical Specifications and Standards for Safety Cages

The safety cages on Plast Hen's fiberglass ladders are designed according to precise technical specifications that ensure maximum safety. The standard cage begins approximately 2 meters from the ladder base, with the bottom section widening to a diameter of about 85 cm for comfortable entry, narrowing to about 75 cm in the upper sections. The structure consists of vertical bars spaced no more than 24 cm apart, and horizontal hoops at intervals of approximately 1.2 meters. The entire structure is positioned about 70-75 cm from the ladder center and designed to provide complete fall protection.

Every ladder system with a safety cage is designed to withstand a concentrated load exceeding 1,100 Newtons per rung, with a 4:1 safety factor based on ultimate strength. For exceptionally tall ladders, Plast Hen installs rest platforms at appropriate intervals according to standard requirements, with each platform surrounded by a safety railing on three sides and capable of supporting significant loads.

The ladders and cages are manufactured using two primary methods: modular construction allowing precise on-site assembly with reinforced connections, or pre-welded assembly in complete units for maximum structural strength. Plast Hen selects the most appropriate method for each application, according to the specific project requirements and site conditions.

Industrial Applications and Customized Solutions

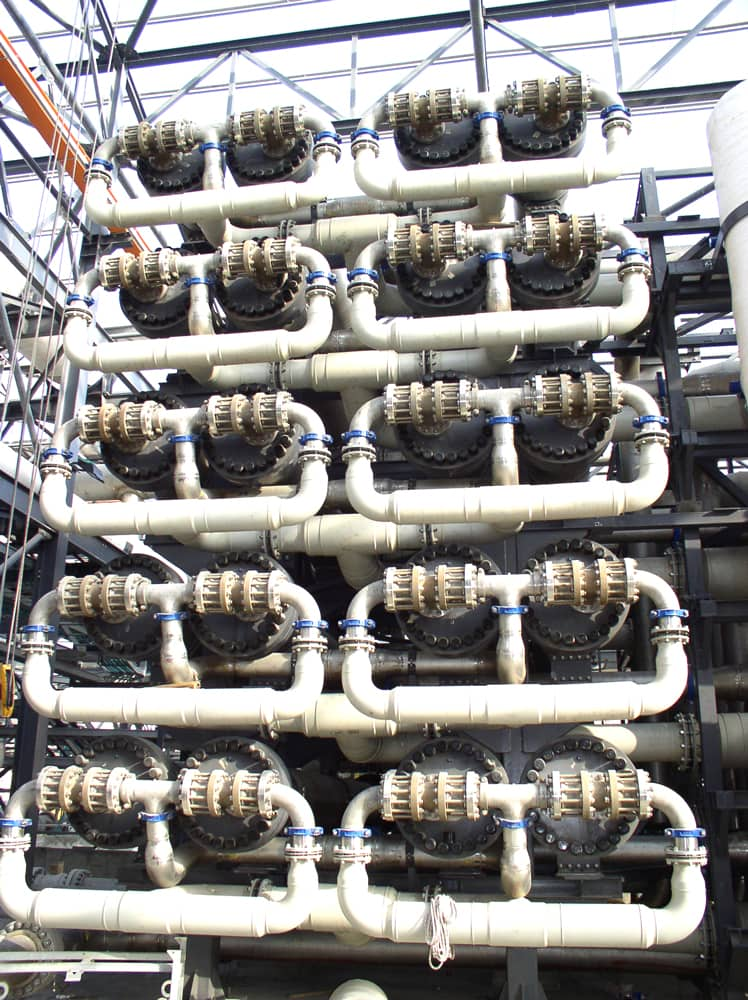

Fiberglass ladders with safety cages from Plast Hen find use in a wide range of industrial applications, each with unique requirements. In chemical plants and refineries, the ladders must comply with ATEX requirements for explosive atmospheres, with certifications for classified zones. Fiberglass provides a significant advantage in these environments due to its anti-static properties preventing electrostatic discharge, and its resistance to prolonged chemical exposure.

In water treatment facilities, Plast Hen's ladders successfully address the unique challenges of chemical exposure and perpetual moisture conditions. Fiberglass does not rust or deteriorate in these conditions, and the ladder surfaces are designed for maximum slip resistance. In power generation facilities, the non-conductive properties of fiberglass make it the preferred choice near electrical equipment, where the ladders eliminate grounding requirements and significantly reduce arc flash risks.

One of the most significant applications for fiberglass ladders is in the food and pharmaceutical industries. In these environments, the smooth structure and sanitary design of Plast Hen ladders allow for easy cleaning and effective disinfection, while meeting stringent FDA requirements. The ladders are also designed with pest prevention features and support for regular disinfection protocols, essential for these sensitive industries.

Maintenance and Lifespan of Fiberglass Ladders

One of the most significant advantages of fiberglass ladders is their minimal maintenance requirements over time. Unlike steel ladders requiring periodic painting and corrosion treatment, or aluminum ladders sensitive to certain materials, Plast Hen's fiberglass ladders are designed to operate almost maintenance-free for decades.

Nevertheless, even fiberglass systems require a regular inspection protocol to ensure maximum safety. Plast Hen recommends a simple visual inspection before each use, identifying visible defects such as cracks, fractures, or distortions. Additionally, more comprehensive periodic inspections by qualified professionals are required, focusing on rung-to-rail connections, cage attachments, and assessment of long-term environmental effects.

While common failure points in metal ladders relate to corrosion and bolted connections, in fiberglass ladders, special attention should be paid to connections between different sections and areas exposed to intensive UV radiation over time. Plast Hen provides comprehensive documentation for each system, including inspection records, installation certifications, and load test certificates, ensuring full compliance with regulatory requirements and efficient monitoring of the system's condition throughout its lifespan.

Conclusion: Choosing Plast Hen's Fiberglass Ladders

Fiberglass ladders with safety cages from Plast Hen represent the technological frontier in height safety. They combine unique features such as complete electrical insulation, excellent chemical resistance, and exceptionally long lifespan, with advanced safety design meeting the most stringent standards.

In a world where safety requirements and regulations are rapidly changing, Plast Hen provides a comprehensive solution, from professional consultation and precise design, through high-quality manufacturing, to professional installation and support service throughout the product's life. The combination of advanced materials, precise manufacturing technology, and deep understanding of industry needs makes Plast Hen's fiberglass ladders the preferred choice in a wide range of industrial applications.

Investment in quality fiberglass ladders represents an investment in worker safety, system reliability over time, and low operating costs. With the global trend toward more advanced safety solutions, Plast Hen's fiberglass ladders represent the future of safe work at height.

For professional advice and a quote for fiberglass ladders with safety cages tailored to your facility's specific needs, contact Plast Hen at 08-6650111 or via email: office@plast-hen.co.il.